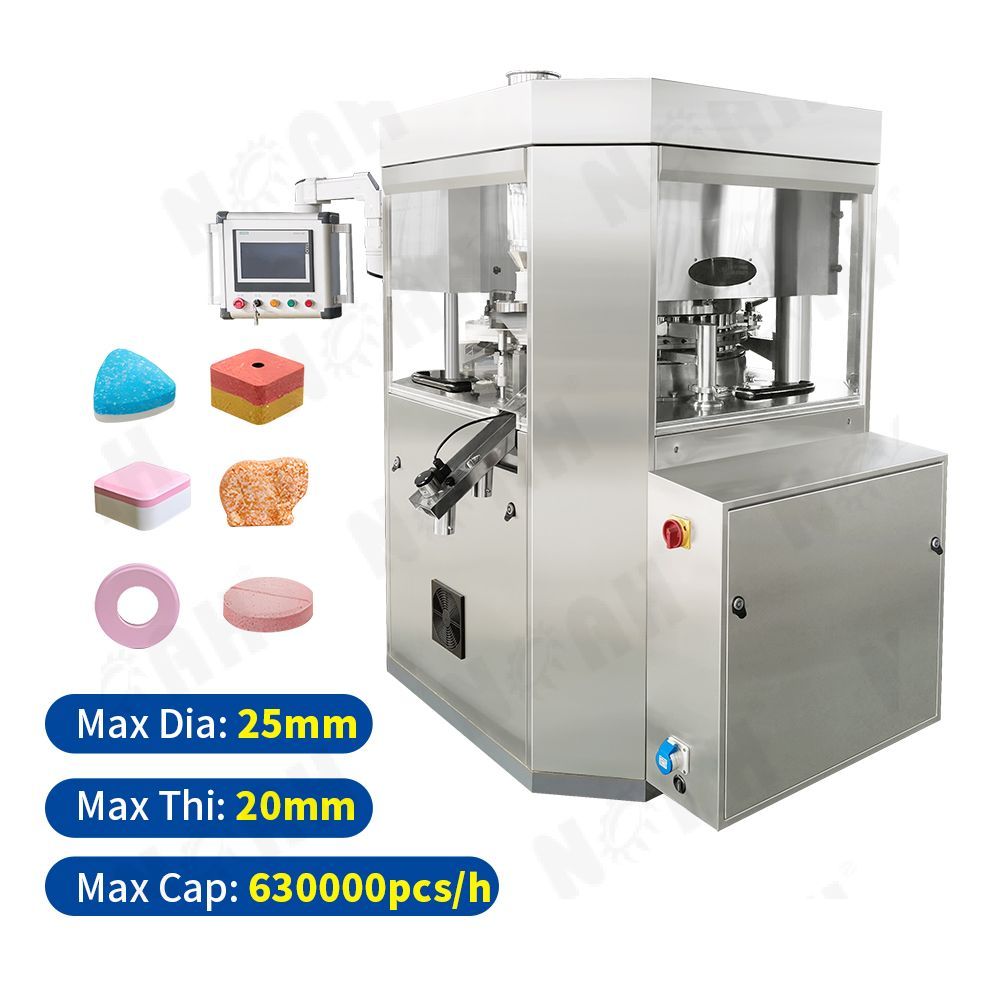

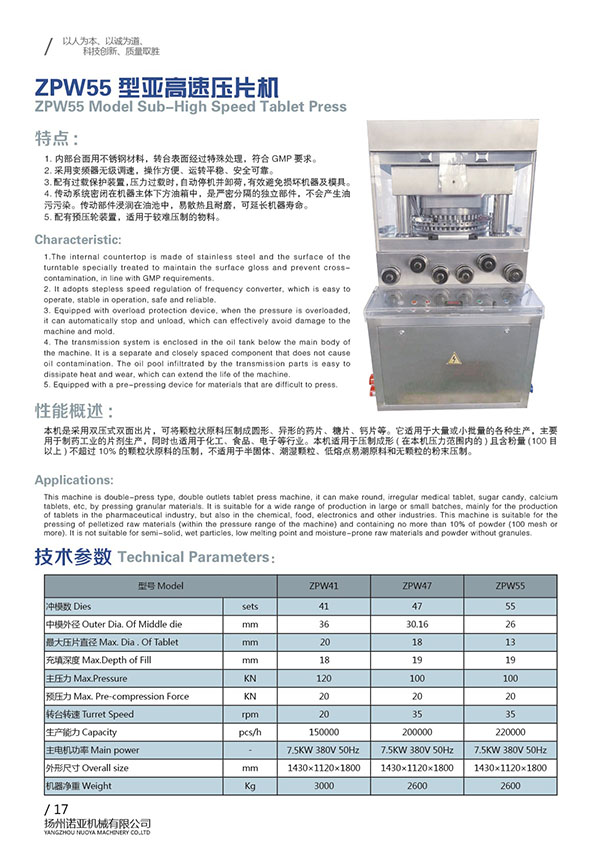

The ZPW125 Three-color Rotary Tablet Press finds application in various industries, including pharmaceutical, foodstuff, chemical, ceramic, electronic, and battery industries. It is designed to press different types of granular materials into tablets, offering versatility in tablet production.

ZPW125 Three-color Rotary Tablet Press

Elevate your tablet production with our advanced tablet press solutions.

Download

Download