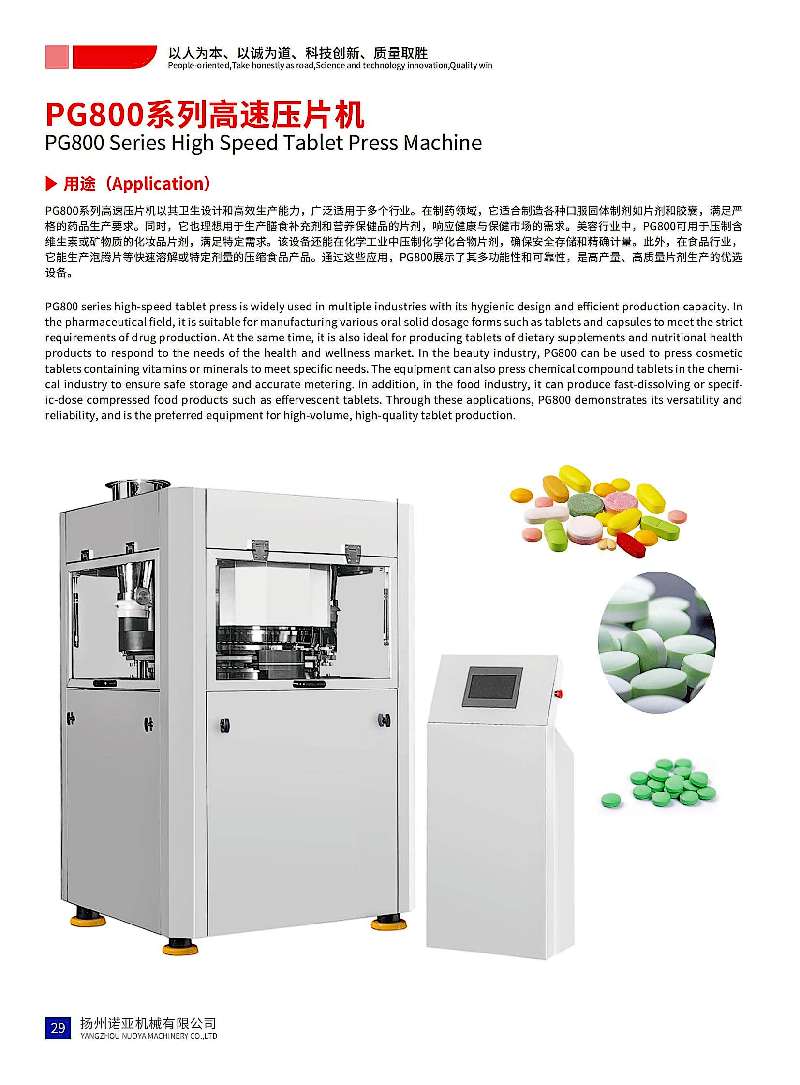

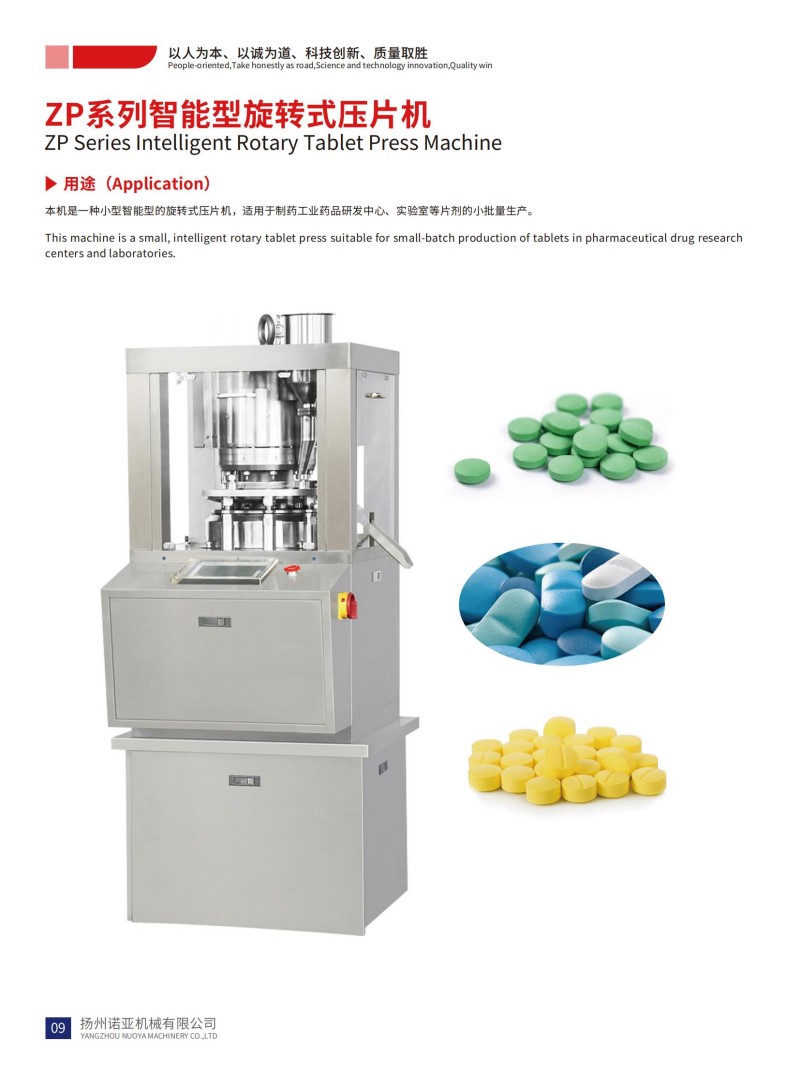

● Pharmaceutical industry: Used for compressing various pharmaceutical solid dosage forms, including immediate-release tablets, sustained-release tablets, chewable tablets, and effervescent tablets, to meet large-scale production demands for medicinal tablets.

● Health supplement sector: Applied in manufacturing nutritional supplement tablets such as vitamin tablets, mineral compound tablets, herbal extract tablets, and protein tablets, suitable for high-efficiency production of health products.

● Food industry: Suitable for producing compressed food tablets like tablet candies (e.g., mint tablets, fruit-flavored tablets), milk tablets, and functional food tablets (e.g., probiotic tablets), adapting to food-grade tablet production standards.

● Chemical industry: Utilized in pressing industrial tablets such as catalyst tablets, detergent tablets, and desiccant tablets, meeting the forming needs of granular/ powdery chemical materials.

● Veterinary medicine field: Employed to manufacture veterinary tablets, including animal drug tablets and animal nutrient supplement tablets, catering to the mass production requirements of veterinary solid preparations.

Download

Download