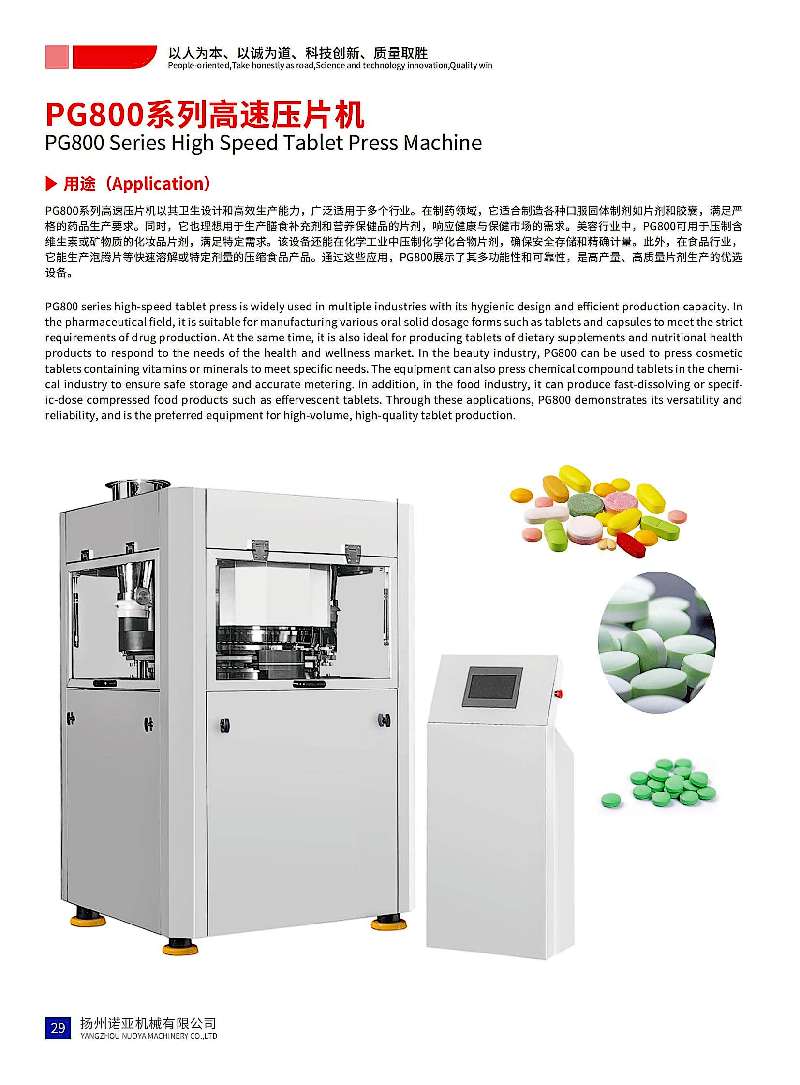

● Pharmaceutical Industry: Widely used for efficient, large-scale production of prescription and over-the-counter tablets under GMP standards.

● Nutraceutical Industry: Ideal for manufacturing accurate-dose vitamin, mineral, and herbal supplement tablets in various shapes and sizes.

● Food Industry: Compresses functional food powders into edible tablets such as instant drinks, sweeteners, or fortified nutrition bars.

● Veterinary Industry: Produces animal health tablets with consistent quality, suitable for diverse species and dosage forms.

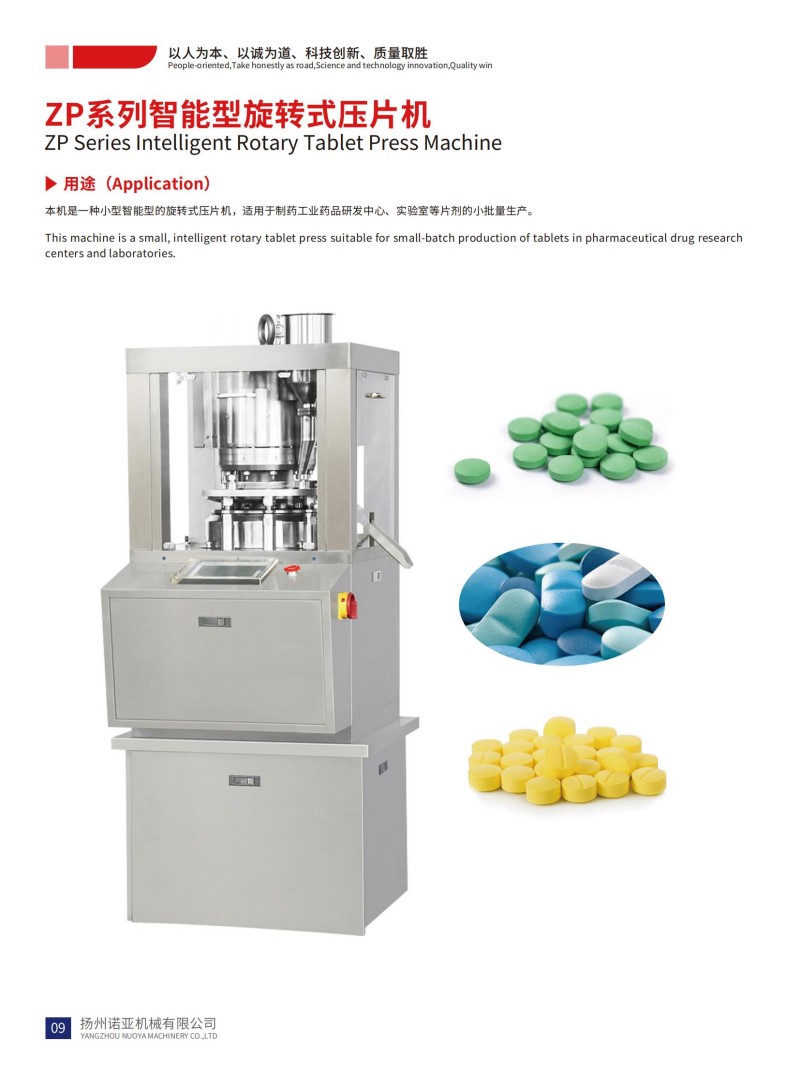

● R&D and Academia: Supports formulation testing and small-batch development with reliable performance and easy operation.

Download

Download