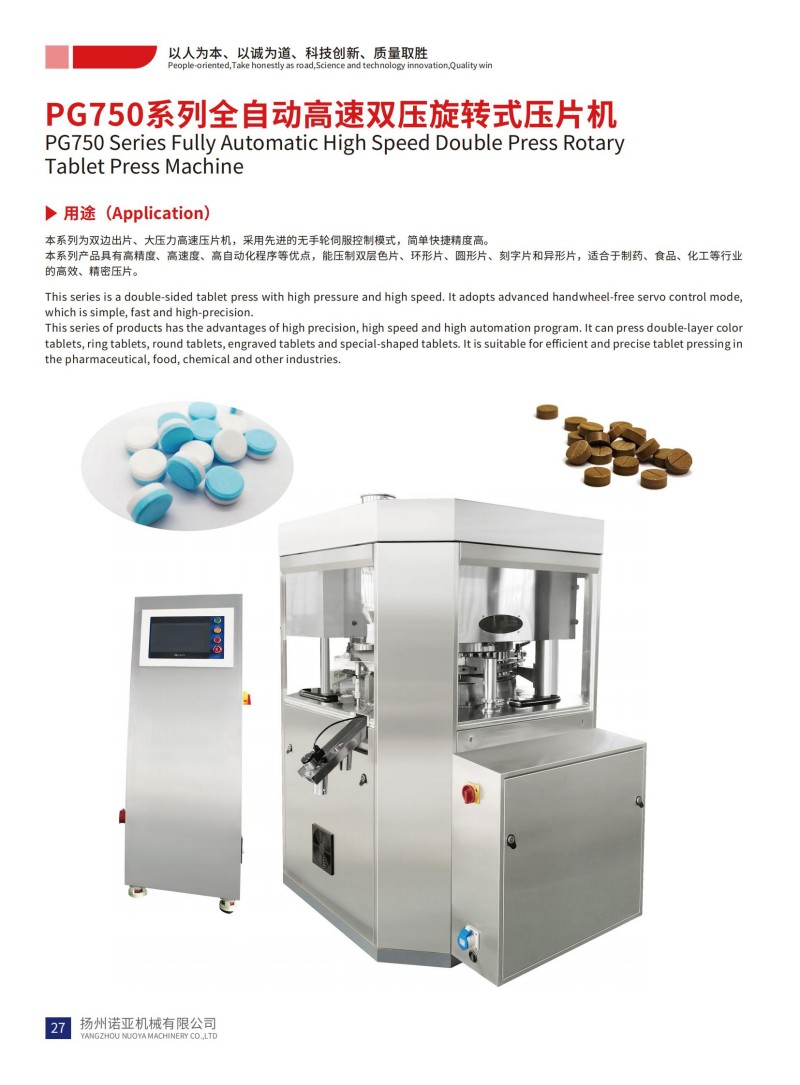

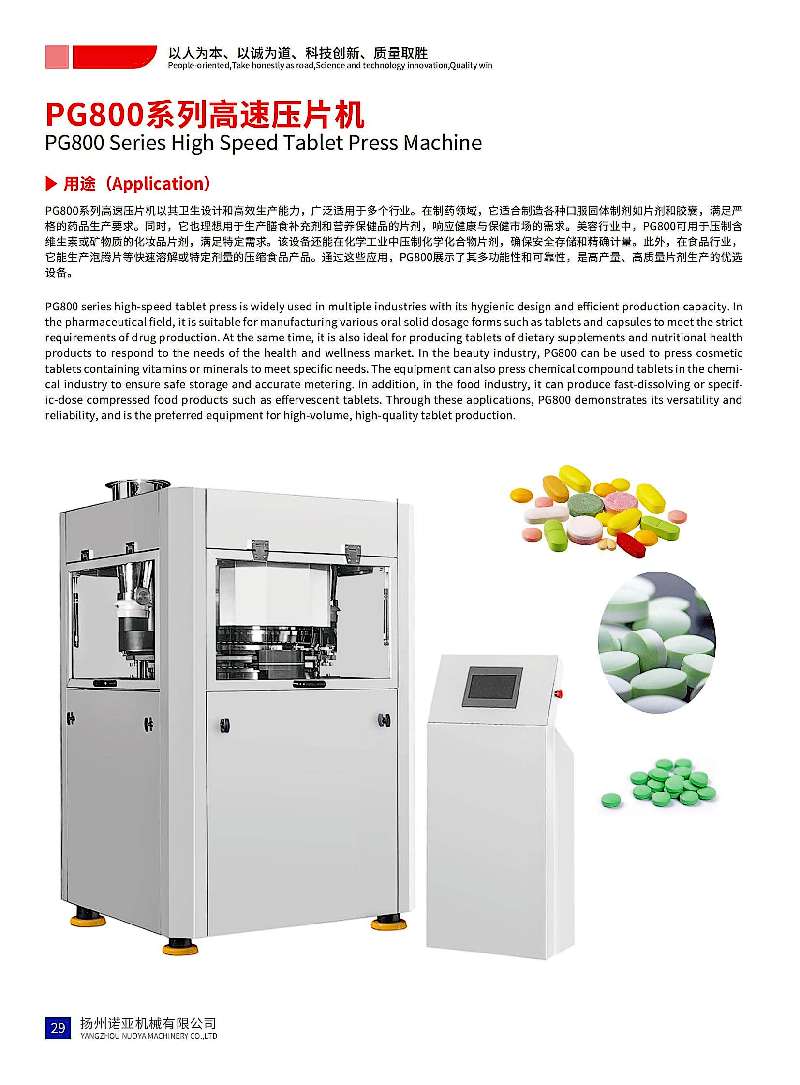

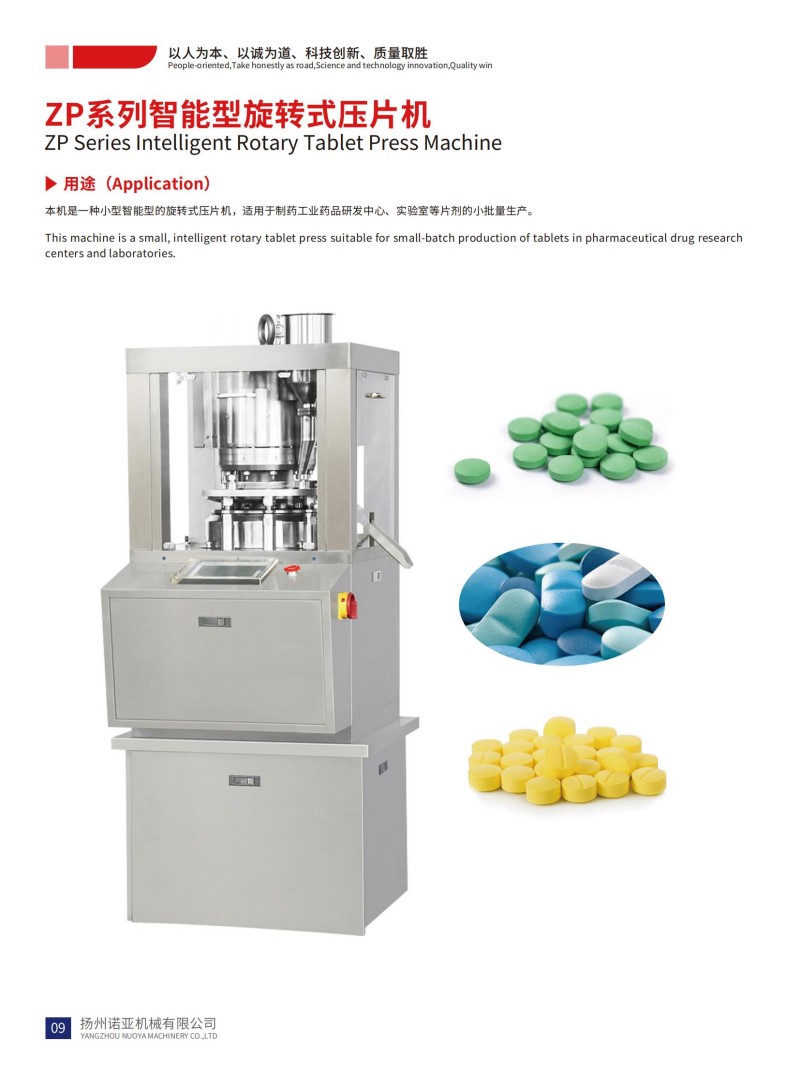

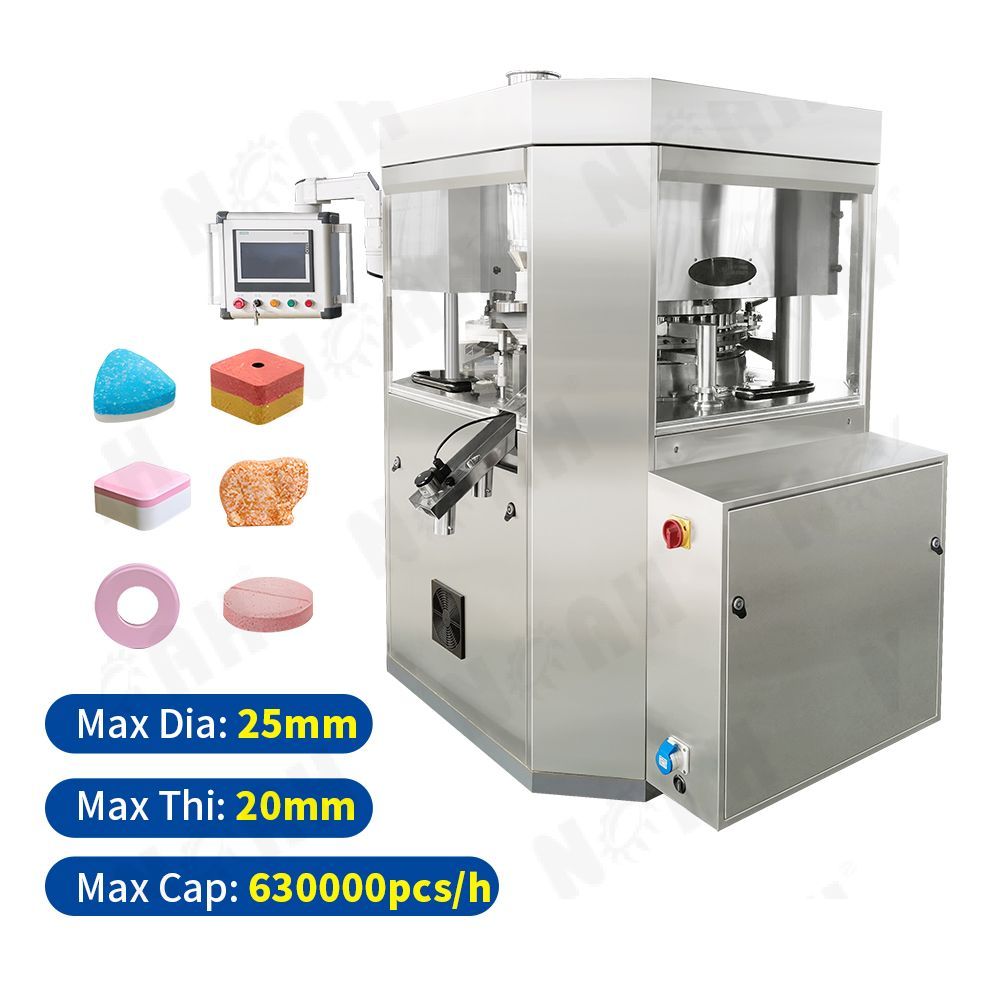

Double-pressing, automatically revolving (double-sided rotary) tablet presses designed for manufacturing tablet prescriptions, capable of producing round pieces, carved characters, special shapes, and double-color pieces; suitable for pharmaceutical, chemistry, foodstuff, and electronics industries.

Features stainless steel construction (ensures surface luster, prevents cross-contamination) and fully closed housing with hardened turret surface, all complying with GMP requirements and enhancing durability.

Equipped with a plexiglass perspective window for easy observation, a fully openable side blank for convenient cleaning, and a powder-absorbing apparatus.

● Boasts well-organized monitors/operating components, frequency-changing speed regulation, overload protection, and high-speed production capability with a large quantity of punches.

● Incorporates a touchscreen interface for user-friendly operation, semi-automatically lubricating equipment (supplemented by automatic lubrication system), anti-dust cover, sealed transmitting system, and sensor pressure protection device.

● Includes a force feeder to improve granule flowability and filling precision, plus a tableting system that ensures consistent tablet weights with adjustable pressure and continuous pre-pressure.

● Compatible with ZP33 products for standardization; moulds are interchangeable with ZP19, ZP33, ZP35, and ZP37 models, offering versatility and compatibility.

Download

Download