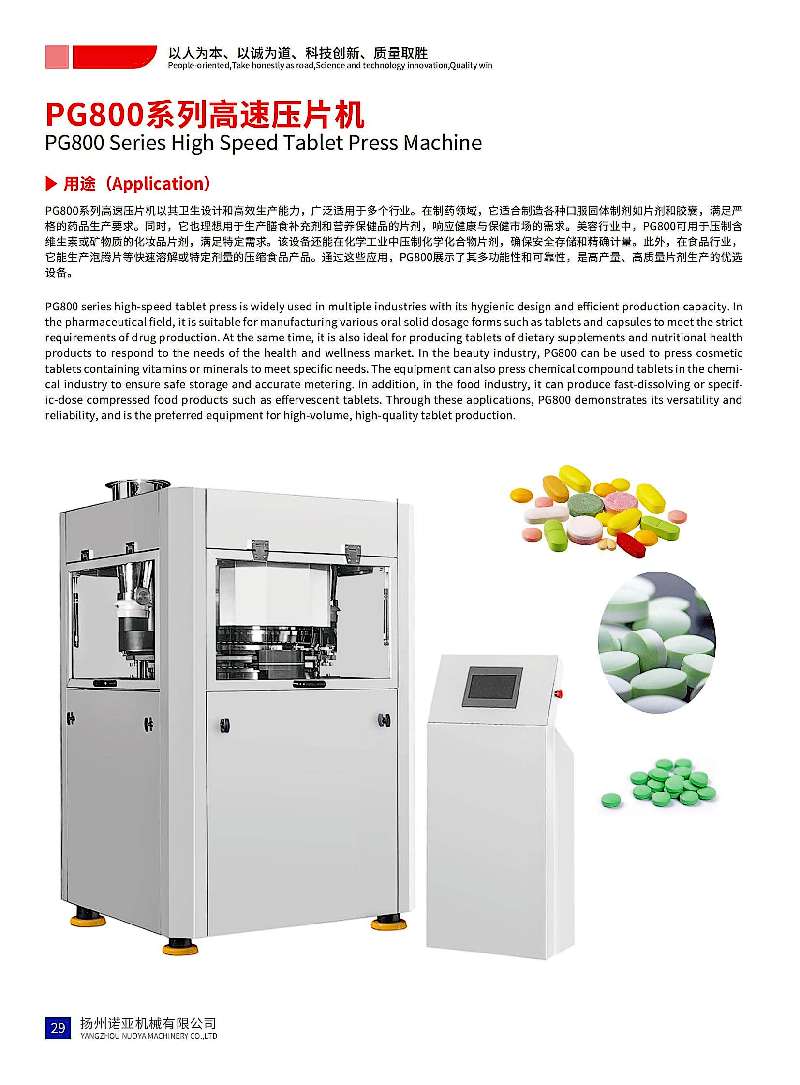

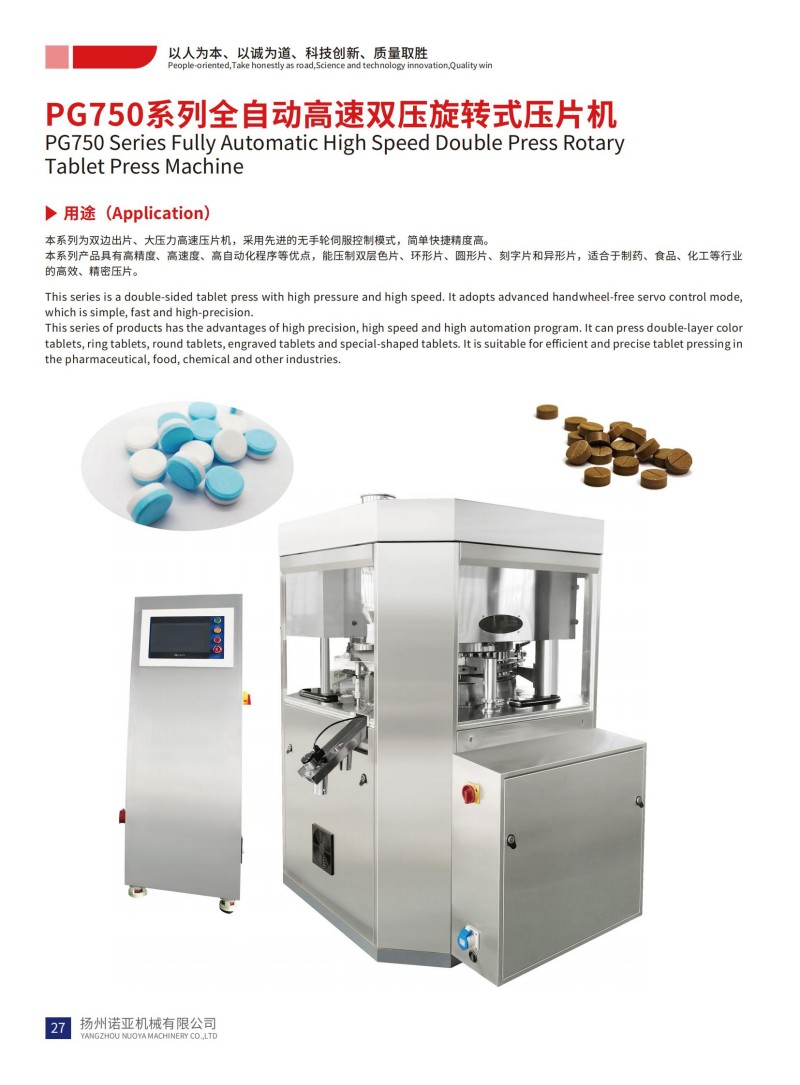

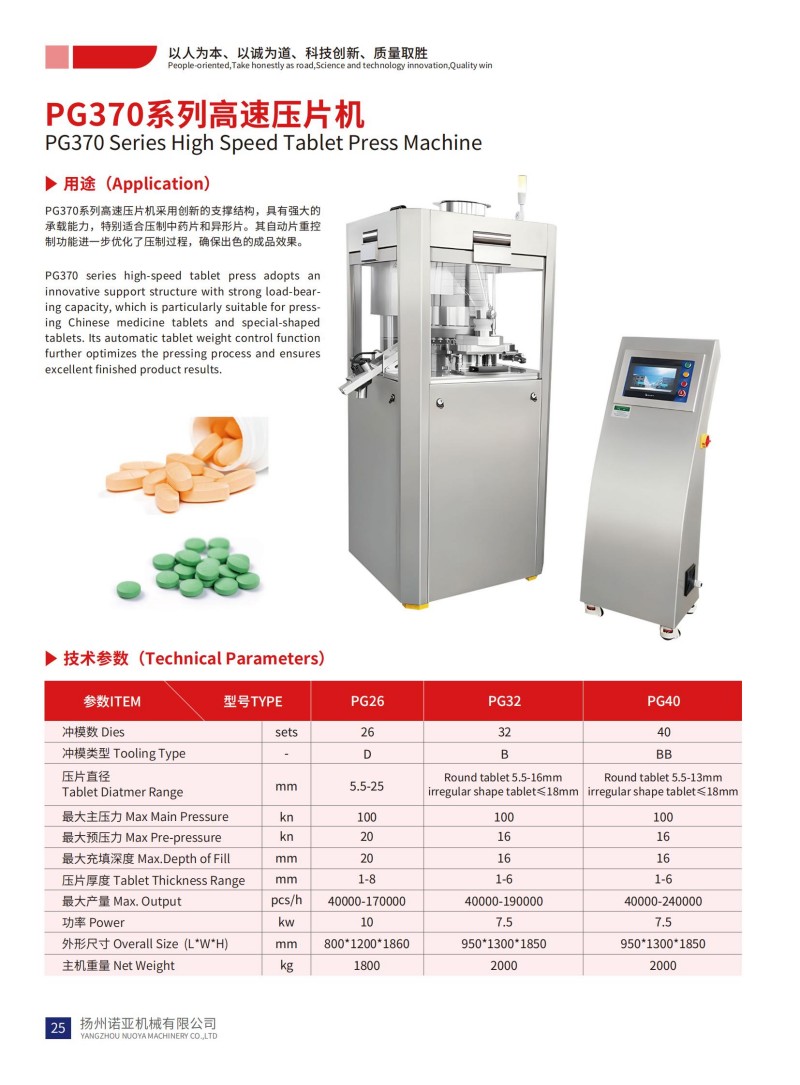

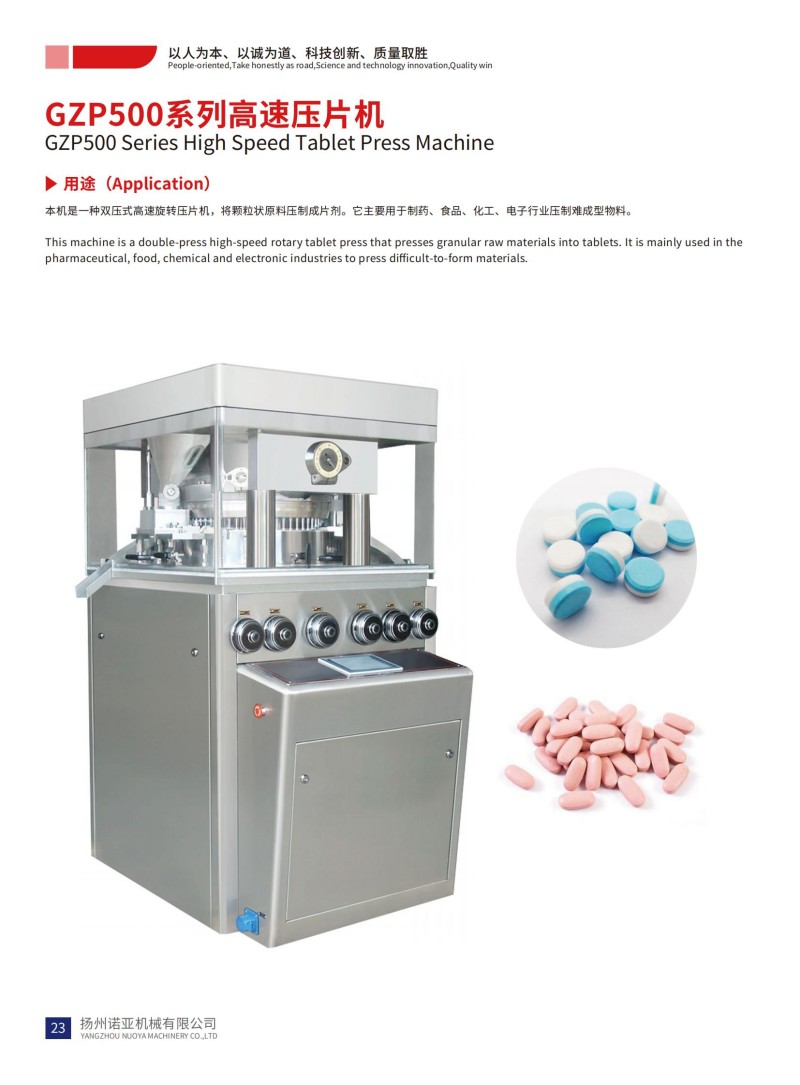

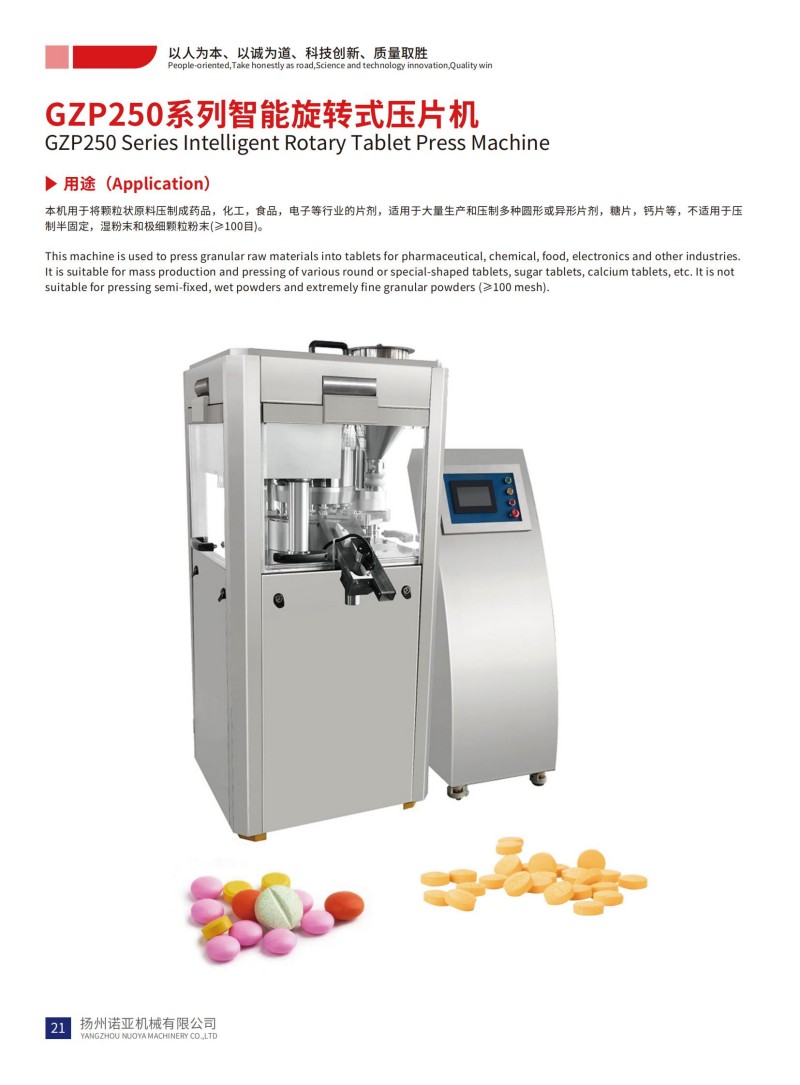

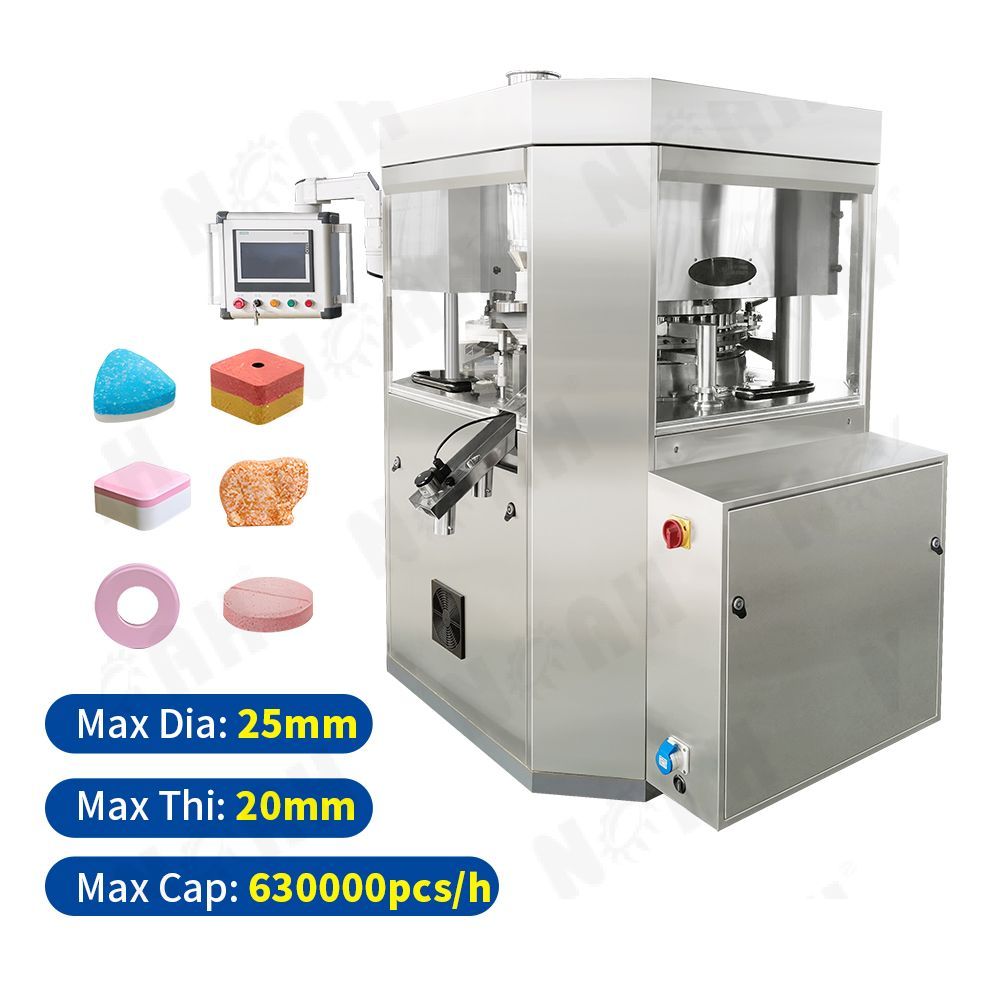

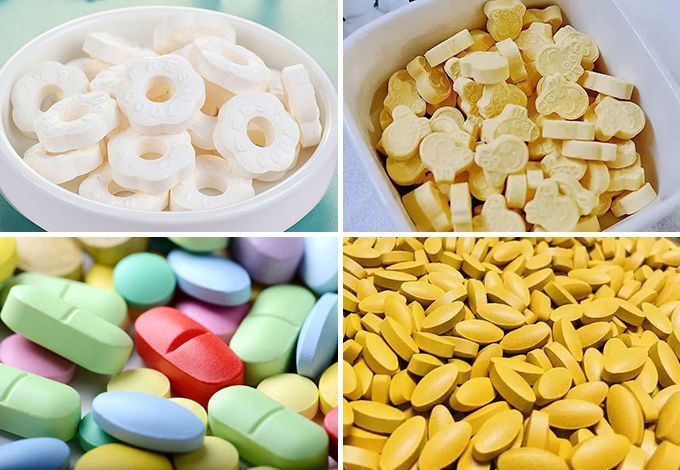

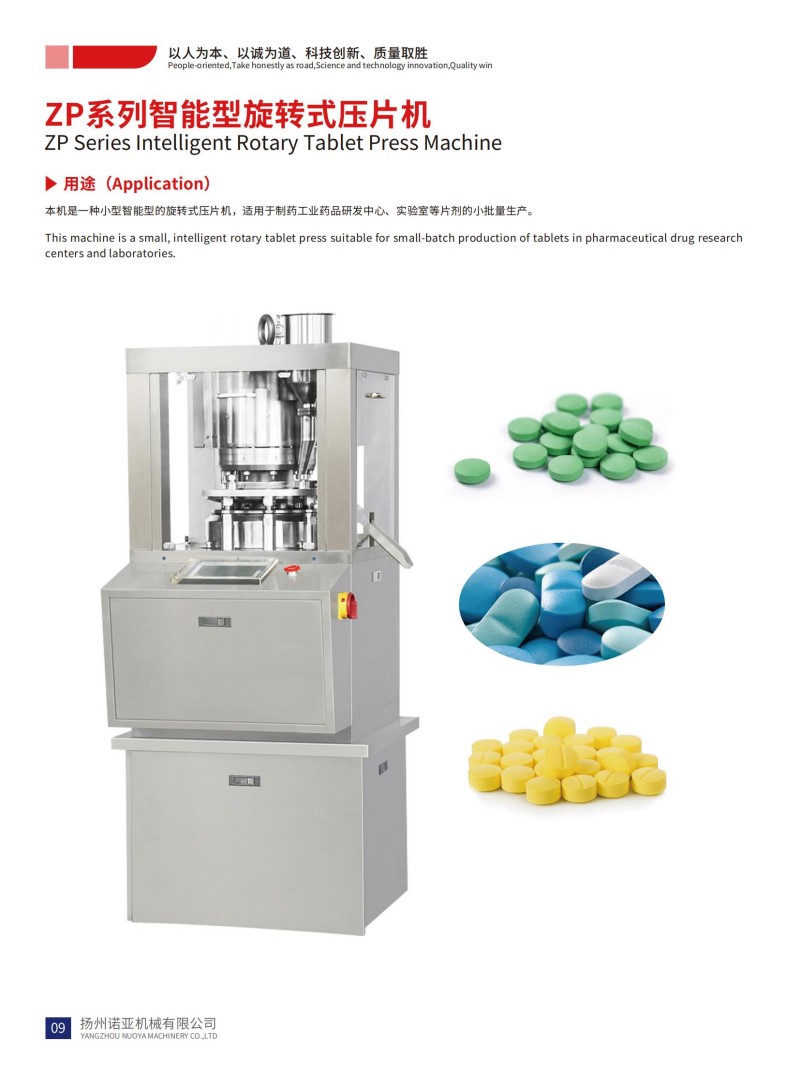

● Pharmaceutical Manufacturing: Producing high-quality tablets, capsules, and specialty pharmaceuticals with precision and consistency

● Food Production: Creating nutritional supplements, vitamins, and functional food tablets

● Chemical & Material Processing: Manufacturing catalysts, chemical pellets, and industrial compounds

● Cosmetics & Personal Care: Producing beauty supplements, skincare tablets, and wellness products

Download

Download