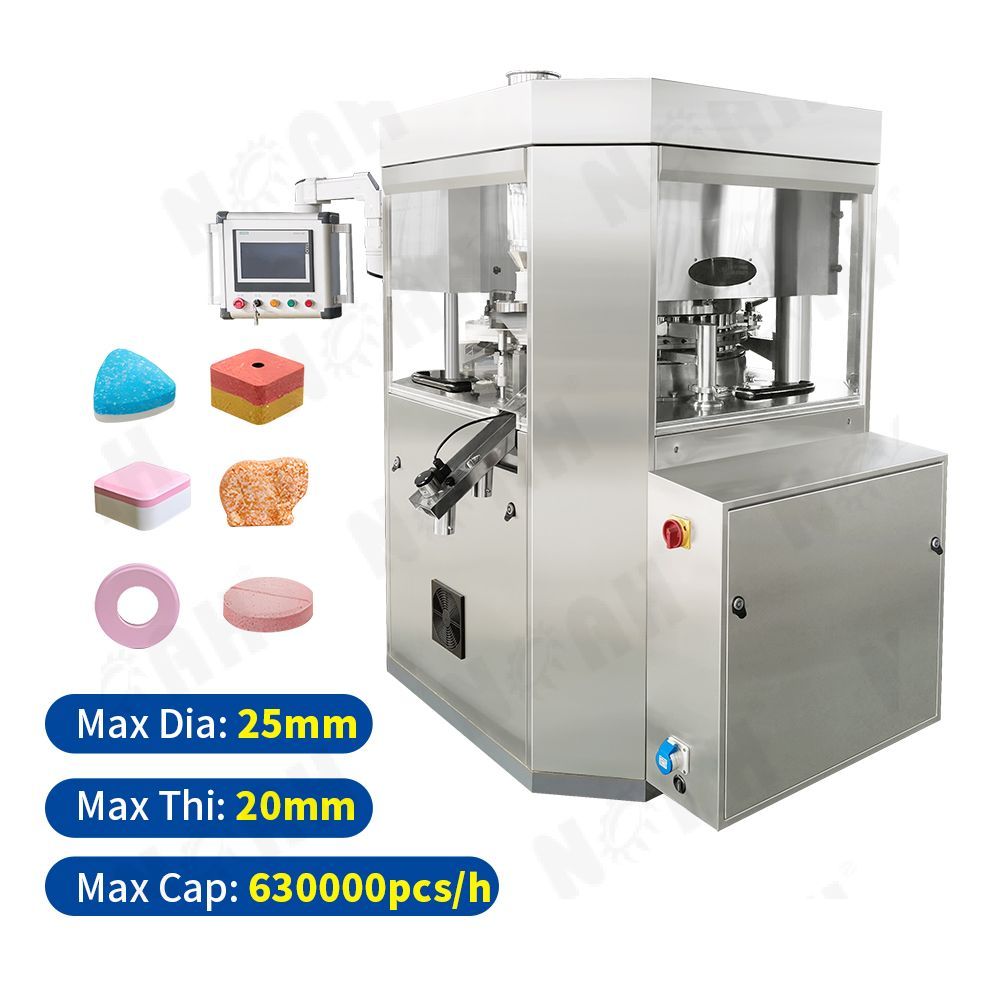

● A new-type compressor machine developed by the company based on market needs, designed for compressing multi-step goods.

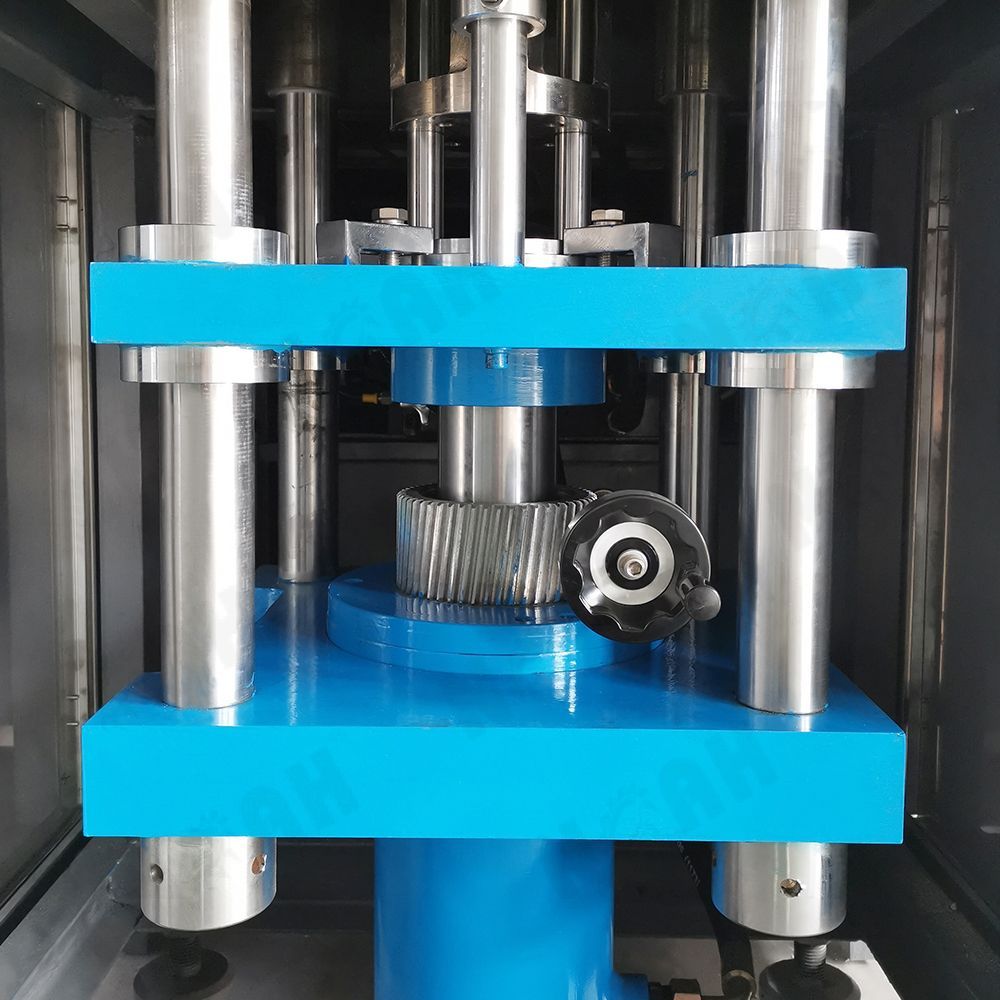

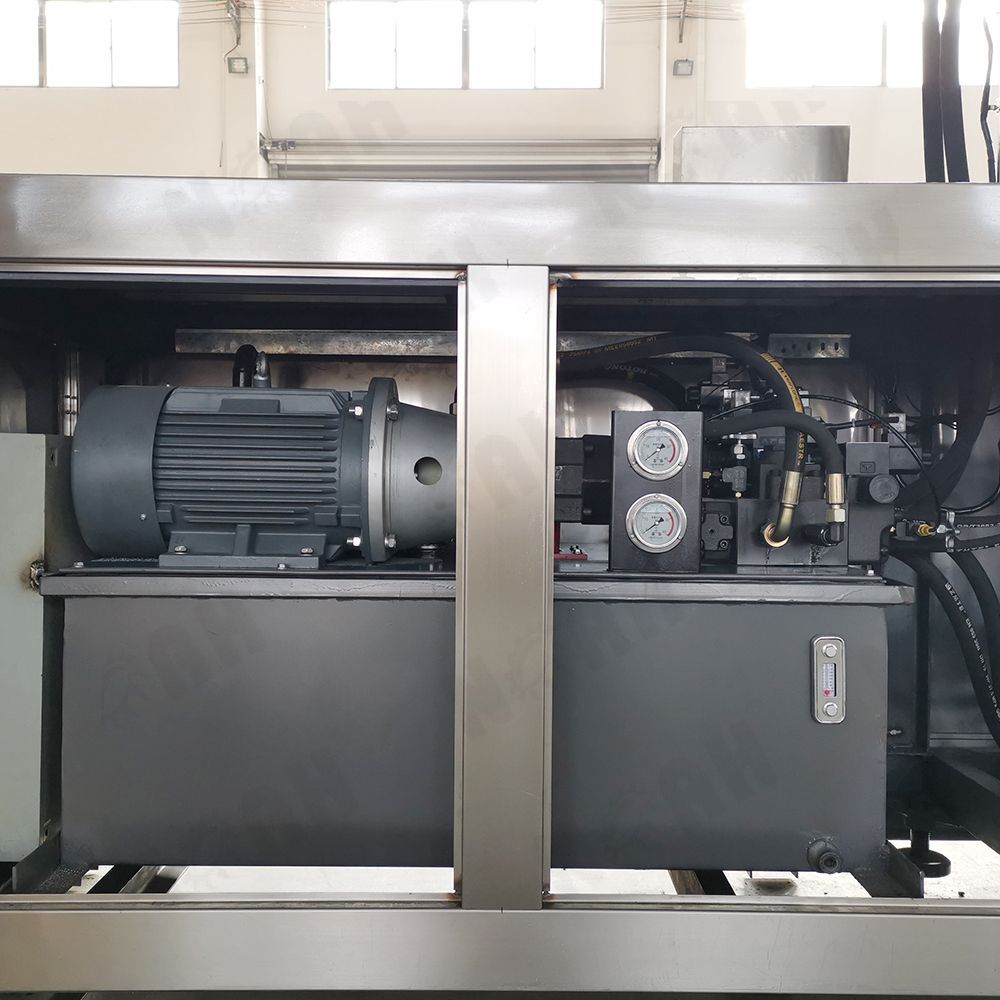

● Integrates the functions and characteristics of several molds into one machine, with advantages including great pressure, high accuracy, stable compression, and reliable performance.

● Saves time and labor while ensuring high production efficiency.

● Ideal for compressing and forming various powder materials, such as dichlorobenzene, silicon powder, carbon powder, ceramics powder, and grinding devices/materials.

Download

Download