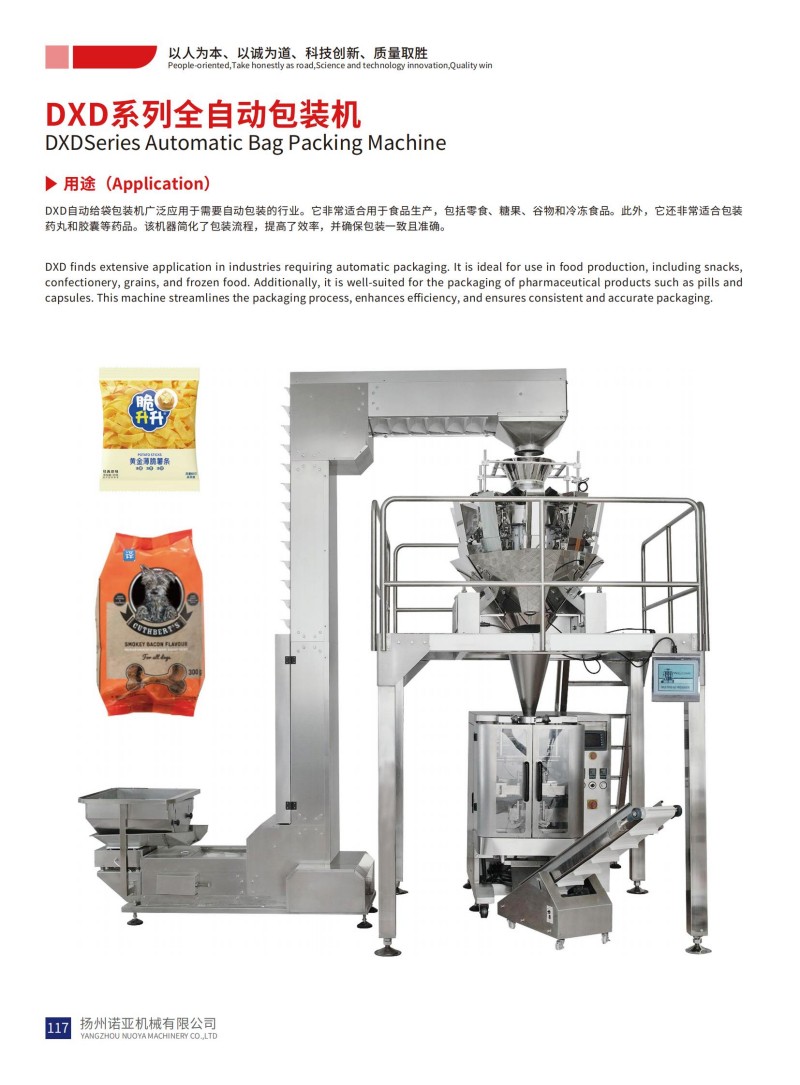

This machine is suitable for granular, powdered, sauce-liquid objects in products in food, chemical, pharmaceutical and other industries, such as beans, peanuts, melon seeds, tea, chili sauce, jelly, vinegar bags and other items.

The machine can be equipped with an assembly line, with stable performance and a wide range of applications.

Download

Download