DC-3 Series Semi-automatic Powder Quantitative Packing Machine is suitable for filling powders that require high precision measurement. It is especially ideal for powder products with strict accuracy requirements, such as chemicals, pharmaceutical raw materials, food additives, and more. This equipment addresses the issue of lower measurement precision associated with vertical auger feeding and features a clamp bag device, making operation simpler. Users only need to position the bag and perform sewing.

DC-3 Semi-automatic Powder Quantitative Packing Machine

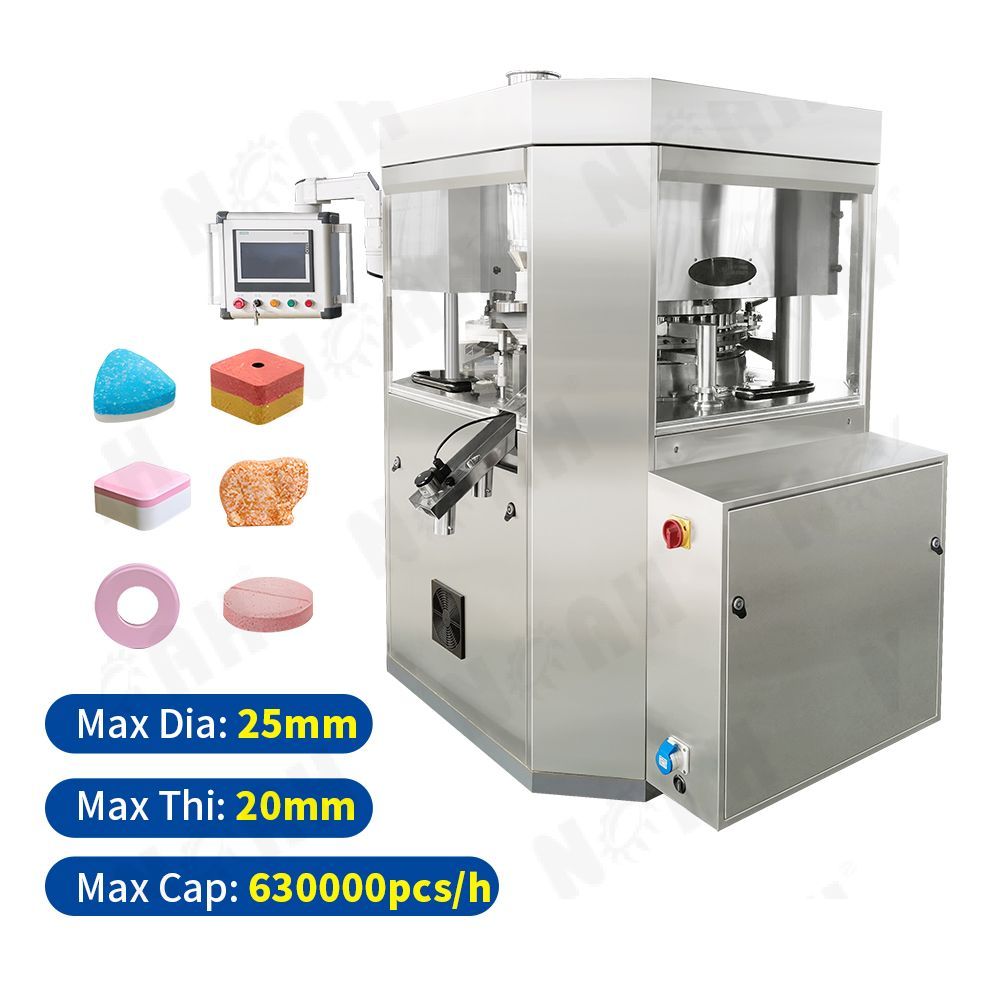

Optimize your pharmaceutical production line with our advanced Automatic Filling Machine, ensuring seamless automation and exceptional accuracy for precise and efficient filling.

Download

Download