fluid bed spray granulator

Enhancing Pharmaceutical Granulation with Fluid Bed Spray Granulator

In pharmaceutical manufacturing, a fluid bed spray granulator is a vital piece of equipment used in the granulation process to create uniform and high-quality granules. Let's delve into the significance of fluid bed spray granulators and their role in pharmaceutical production.

Fluid Bed Spray Granulator: Key Equipment in Granulation

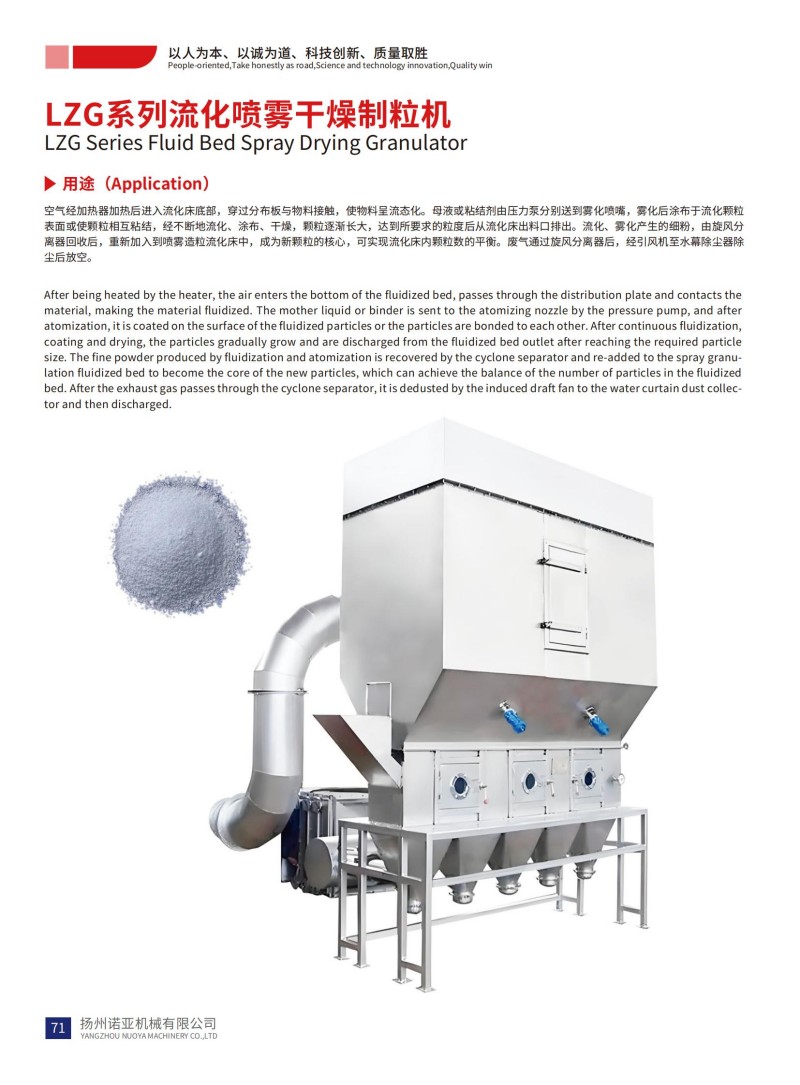

A fluid bed spray granulator is a versatile machine used to granulate powders by spraying a binder solution onto fluidized powder particles. This process forms granules of controlled size, density, and porosity, essential for the production of pharmaceutical tablets and capsules.

Benefits of Using a Fluid Bed Spray Granulator

Fluid bed spray granulators offer several advantages in pharmaceutical granulation, including uniform granule size distribution, controlled granule properties, efficient drying capabilities, and the ability to coat granules for modified release formulations.

Applications of Fluid Bed Spray Granulation in Pharmaceuticals

Fluid bed spray granulation is commonly used in pharmaceutical manufacturing to produce granules with specific characteristics, such as improved flow properties, compressibility, and content uniformity. This process is crucial for formulating solid dosage forms.

Importance of Granulation in Pharmaceutical Formulation

Granulation is a fundamental step in pharmaceutical formulation that improves the flow properties of powders, enhances drug stability, and facilitates dose accuracy. Fluid bed spray granulation plays a key role in achieving these objectives effectively.

Optimizing Granulation Processes with Fluid Bed Spray Granulators

By utilizing a fluid bed spray granulator, pharmaceutical manufacturers can optimize granulation processes, ensuring consistent granule quality and enhancing the overall efficiency of pharmaceutical production.

Conclusion

In pharmaceutical manufacturing, a fluid bed spray granulator is a valuable tool for granulating powders and creating high-quality granules essential for tablet and capsule production. Understanding the role of fluid bed spray granulators in pharmaceutical granulation processes is key to achieving efficient and quality-driven manufacturing practices.

Discover a comprehensive range of fluid bed processing equipment, including fluid bed dryers, granulators, and top spray granulation systems. Explore our selection of wet granulation machines and fluidized bed dryers designed for various applications. Whether you need a fluid bed dryer for sale or a lab-scale fluid bed granulator, we offer high-quality solutions to meet your processing needs. From fluid bed spray granulators to top spray fluid bed granulation systems, find the perfect equipment for your granulation and drying processes. Enhance your operations with efficient and reliable fluid bed processing technology.

Enhancing Pharmaceutical Manufacturing Efficiency with Advanced Fluid Bed Processing Technologies

In the realm of pharmaceutical manufacturing, fluidized bed processing technologies have become indispensable for their ability to efficiently dry, granulate, and coat particles in a controlled and uniform manner. From fluid bed dryers to granulators and spray systems, these technologies play a pivotal role in optimizing production processes and ensuring product quality.

Fluidized Bed Dryer:

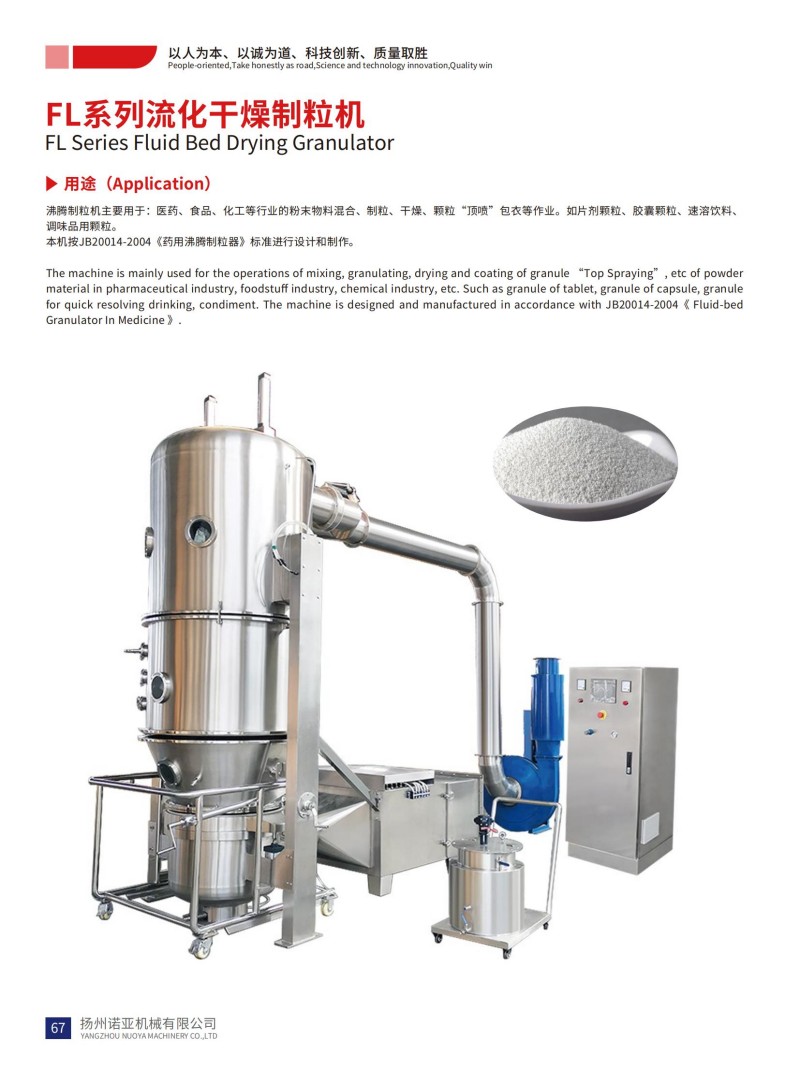

A fluidized bed dryer is a cornerstone in pharmaceutical manufacturing, providing a reliable and efficient method for drying granules, powders, and pellets. By utilizing a stream of heated air to fluidize and dry particles evenly, these dryers facilitate rapid and uniform drying processes, crucial for maintaining product integrity.

Fluid Bed Dryer Granulator:

The integration of granulation capabilities into fluid bed dryers enhances their versatility in pharmaceutical production. Fluid bed dryer granulators enable simultaneous drying and granulation of materials, streamlining processes and reducing production time, while ensuring consistent particle size and quality.

Fluid Flow Through Granular Beds:

Understanding the dynamics of fluid flow through granular beds is essential for optimizing fluid bed processing operations. By controlling parameters such as airflow rate, temperature, and bed composition, manufacturers can achieve precise control over granulation, drying, and coating processes in fluidized bed systems.

Fluid Bed Spray Granulator:

Fluid bed spray granulators offer a comprehensive solution for granulating powders and forming uniform granules through spray coating processes. These systems enable precise control over granule size and properties, making them ideal for pharmaceutical applications requiring controlled release formulations and enhanced product stability.

Fluid Bed Granulator Dryer:

Combining granulation and drying functionalities, fluid bed granulator dryers provide a seamless solution for pharmaceutical manufacturers looking to streamline their production processes. These integrated systems offer efficient granulation, drying, and coating capabilities in a single unit, maximizing productivity and product quality.

Fluidised Bed Dryer:

Fluidised bed dryers, known for their efficient drying capabilities and gentle handling of materials, are widely used in the pharmaceutical industry. These dryers create a fluidized layer of particles that promotes rapid and uniform drying, making them ideal for sensitive pharmaceutical formulations requiring precise temperature and airflow control.

Fluid Bed Top Spray Granulation:

Fluid bed top spray granulation systems are instrumental in producing homogeneous granules with controlled characteristics. By precisely spraying liquid binder onto fluidized particles from the top, these systems ensure uniform granule formation, making them ideal for creating multiparticulate dosage forms and modified-release formulations.

In conclusion, the adoption of advanced fluid bed processing technologies is revolutionizing pharmaceutical manufacturing, offering efficient solutions for drying, granulating, and coating pharmaceutical products. From fluidized bed dryers to granulators and spray systems, these technologies empower pharmaceutical manufacturers to optimize their production processes, ensuring consistent quality and performance in their products.

fluid bed dryer

top spray fluid bed granulation

fluid bed granulation

fluid bed dryer granulator

fluid bed dryer wet granulation

fluid bed top spray granulation

wet granulation machine

fluidised bed dryer

wet granulation fluid bed

fluid bed spray dryer granulator

fluid bed dryer for sale

fluidized bed dryer

fluid flow through granular beds

fluid bed spray granulator

fluid bed granulator dryer

lab scale fluid bed granulator

fluid bed spray granulator

wet granulation fluid bed

In the realm of pharmaceutical manufacturing, the fluid bed spray granulator and wet granulation fluid bed are pivotal technologies used in the production of granules for pharmaceutical formulations. These processes play a crucial role in the development of high-quality pharmaceutical products.

The fluid bed spray granulator is a sophisticated equipment that combines drying, granulation, and coating processes in a single unit. This versatile machine is capable of producing uniform granules with controlled particle size distribution, making it an essential tool in pharmaceutical formulation development.

On the other hand, wet granulation in a fluid bed involves the use of a fluidized bed system to create granules from a liquid binder and solid particles. This process is widely employed in the pharmaceutical industry to enhance the flow properties, compressibility, and content uniformity of granules, ultimately improving the quality of the final dosage form.

The wet granulation fluid bed offers several advantages, including precise control over granule size and density, as well as the ability to produce granules with desirable characteristics such as improved dissolution rates and stability. This method is particularly effective for formulations that require uniform blending of active pharmaceutical ingredients with excipients.

In pharmaceutical manufacturing, the utilization of fluid bed technologies for granulation processes has revolutionized the production of solid dosage forms. These advanced technologies not only improve the efficiency of granule production but also ensure the uniformity and quality of the final pharmaceutical products.

Overall, the fluid bed spray granulator and wet granulation fluid bed represent cutting-edge solutions in pharmaceutical manufacturing, enabling manufacturers to produce high-quality granules for a wide range of pharmaceutical formulations. By incorporating these technologies into their production processes, pharmaceutical companies can enhance product quality, optimize manufacturing efficiency, and meet the stringent regulatory requirements of the industry.

Download

Download