Background:

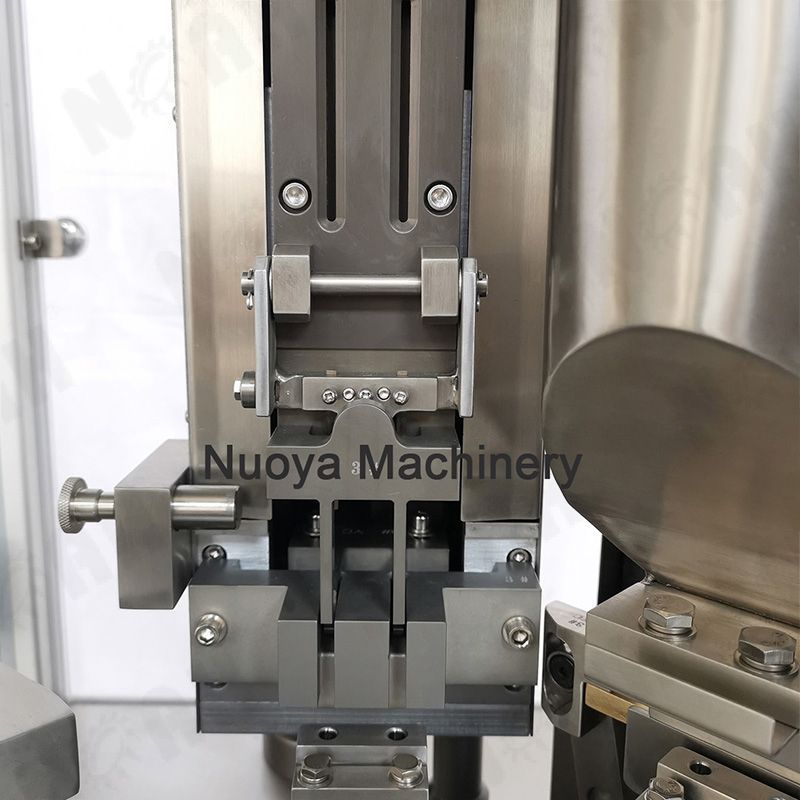

The NJP200-400 Fully Automatic Capsule Filling Machine is a cutting-edge equipment widely used in the pharmaceutical and healthcare industries for efficient and precise capsule filling. In this investment return analysis, we will assess the development prospects of the NJP200-400 machine.

Profit Analysis:

Increased Production Efficiency: The NJP200-400 machine significantly enhances production efficiency with its high-speed filling capability. It can fill a large number of capsules per minute, reducing labor costs and production time. This increased productivity leads to higher output, increased sales, and improved profitability.

Cost Savings: The automation provided by the NJP200-400 machine reduces the need for manual labor, resulting in cost savings for the company. The machine operates with precision and accuracy, minimizing material waste and reducing overall production costs.

Improved Product Quality: The NJP200-400 machine ensures consistent and accurate filling of capsules, resulting in high-quality products. This quality assurance enhances customer satisfaction, increases brand reputation, and potentially leads to higher pricing and market demand.

Market Expansion: With its advanced capabilities, the NJP200-400 machine allows businesses to expand their product offerings. It can accommodate various capsule sizes, filling materials, and dosages, enabling companies to cater to a broader range of customer needs and enter new market segments.

Competitive Advantage: The NJP200-400 machine provides a competitive advantage to businesses in the pharmaceutical industry. Its high-speed operation, precision filling, and versatility set it apart from manual or less advanced filling methods. This differentiation can help attract new customers and gain a larger market share.

Scalability and Flexibility: The NJP200-400 machine offers scalability and flexibility to adapt to changing production needs. It can handle different capsule sizes and filling materials, allowing businesses to expand their product lines or adjust formulations as required.

Investment Return Analysis:

Calculate the payback period to determine the time required to recover the initial investment.

Evaluate the return on investment (ROI) by comparing the net profit generated over a specific period with the initial investment.

Risks and Uncertainties:

Market demand fluctuations, changes in regulations, and competitive pressures may impact the investment return.

Maintenance, repair, and potential obsolescence of the equipment should be considered to ensure long-term viability.

It is advisable to conduct a detailed financial analysis and market research specific to your business to accurately assess the investment return of the NJP200-400 Fully Automatic Capsule Filling Machine. Consultation with financial professionals is recommended before making any investment decisions.

Download

Download