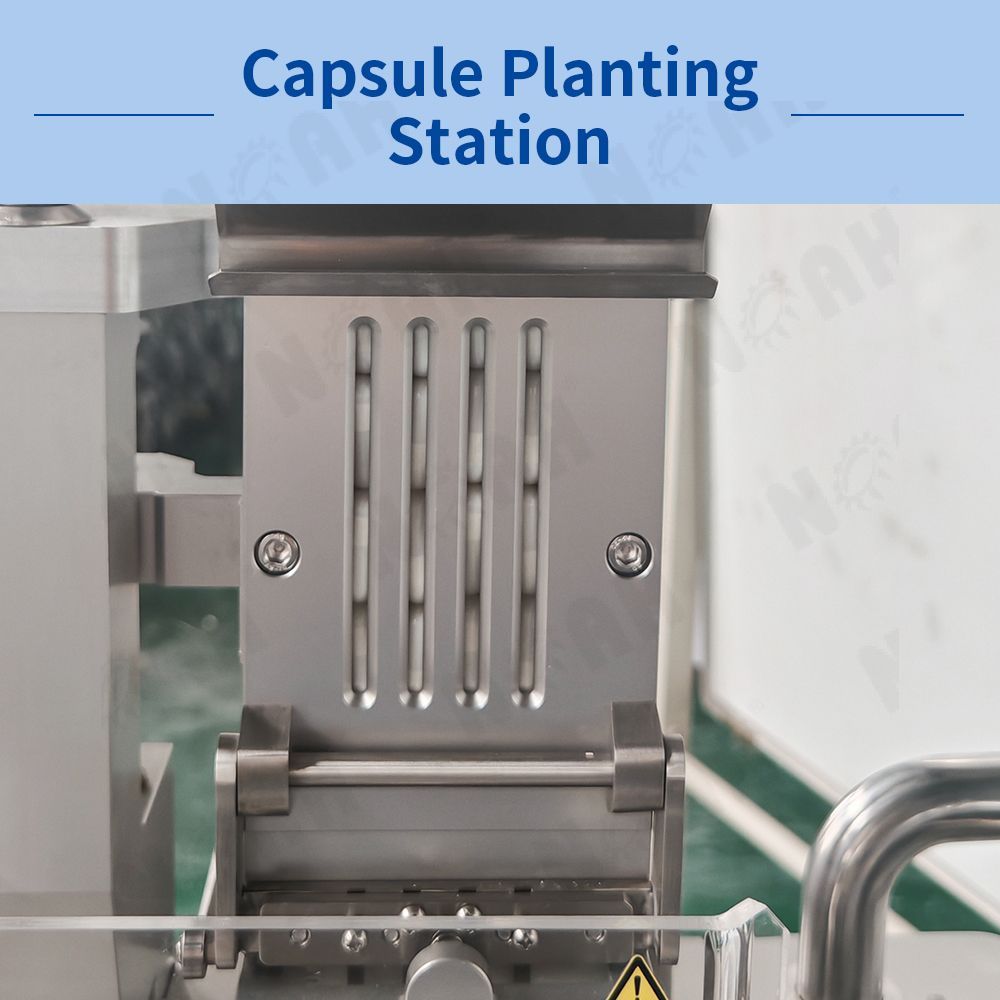

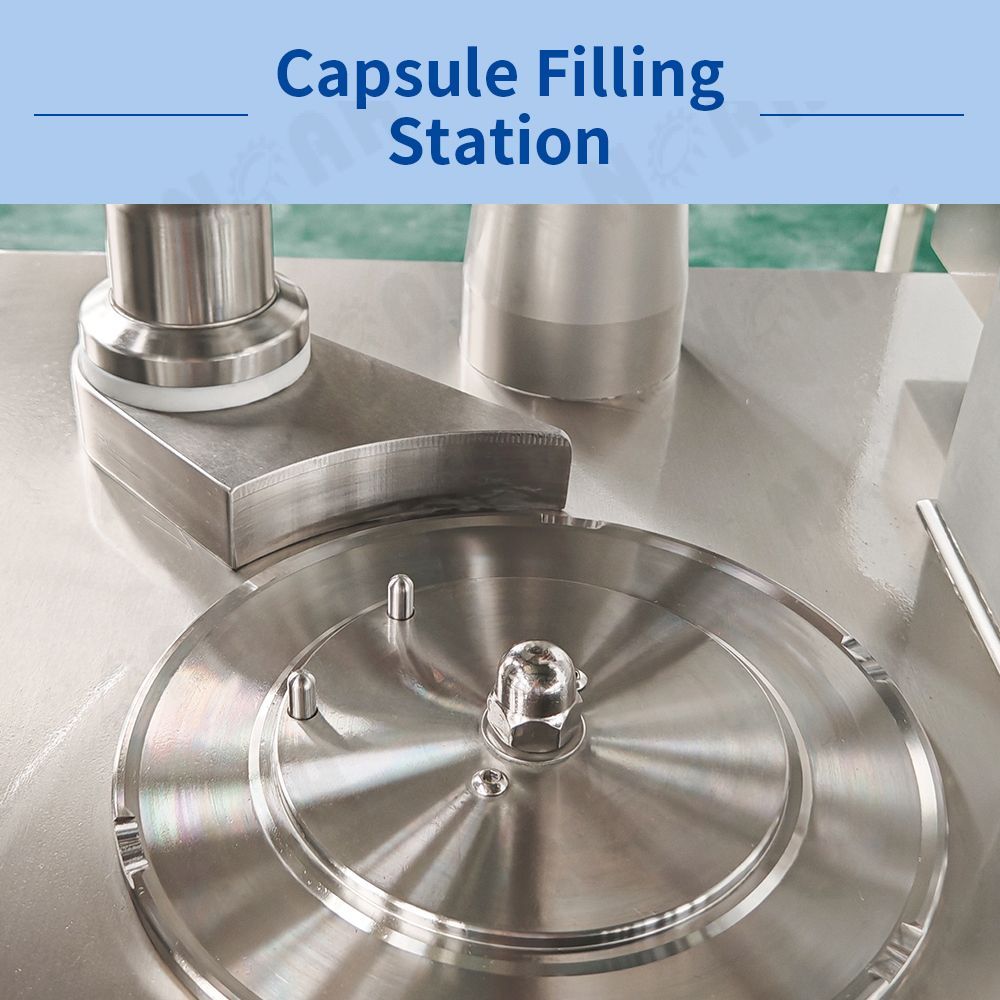

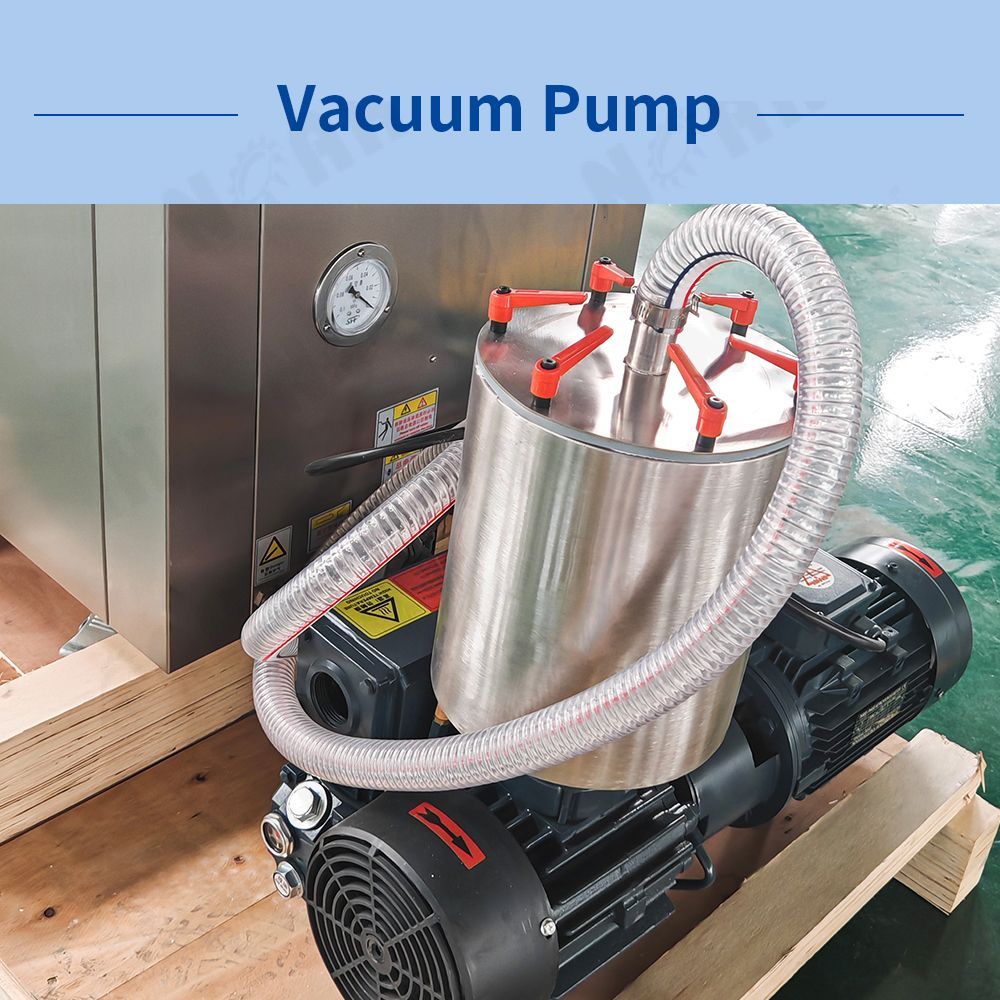

The JTJ-I Semi-automatic Capsule Filling Machine is specifically designed for use in medium and small pharmaceutical factories, hospital preparation labs, and similar environments. It is ideal for filling capsules with powder and granules. This machine is widely used in the production of pharmaceutical products, allowing for precise dosing and efficient operation.

JTJ-I Semi-automatic Capsule Filling Machine

Discover the perfect solution for efficient and precise capsule filling with our top-of-the-line capsule-filling machine.

Download

Download