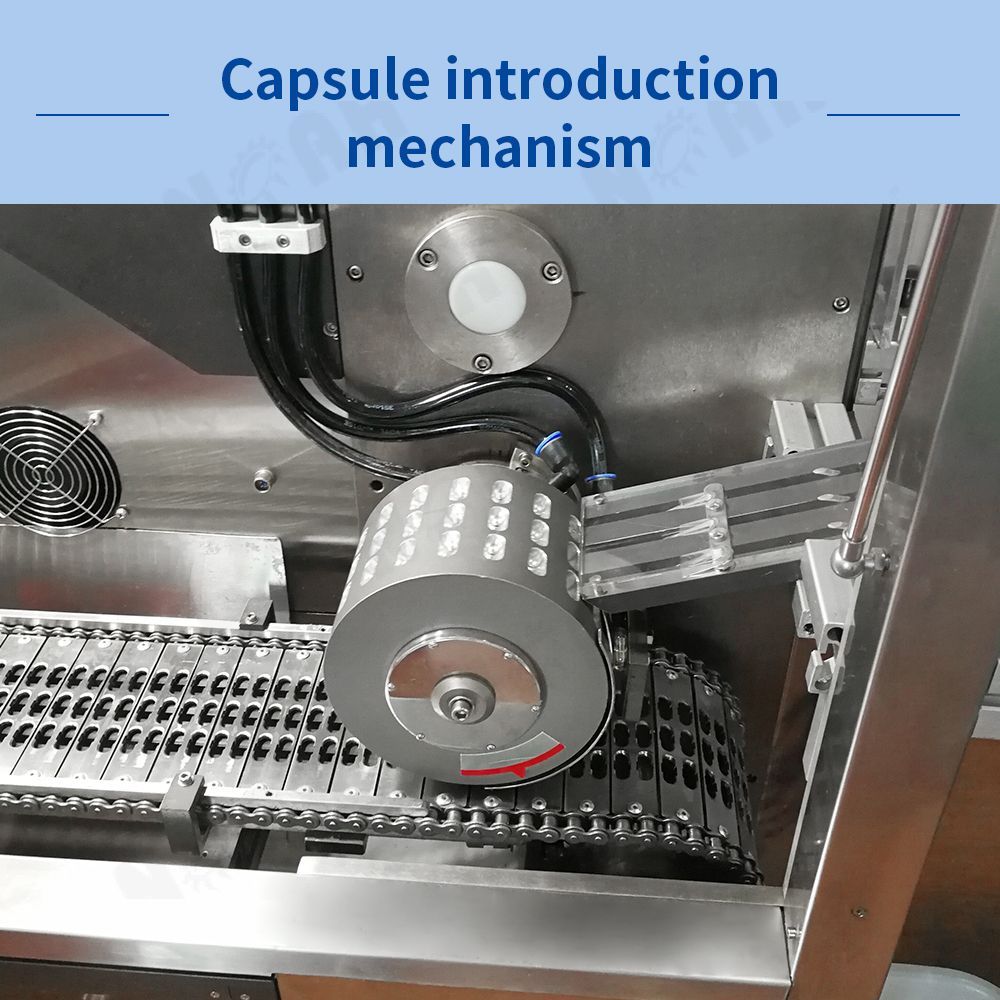

● Stable Operation: High-precision indexing drive ensures smooth running with low noise, a hallmark of NOAH’s equipment quality.

● Durable Components: Fully enclosed turntable and original Japanese linear oil-free bearings extend equipment service life, reflecting NOAH’s focus on long-term usability.

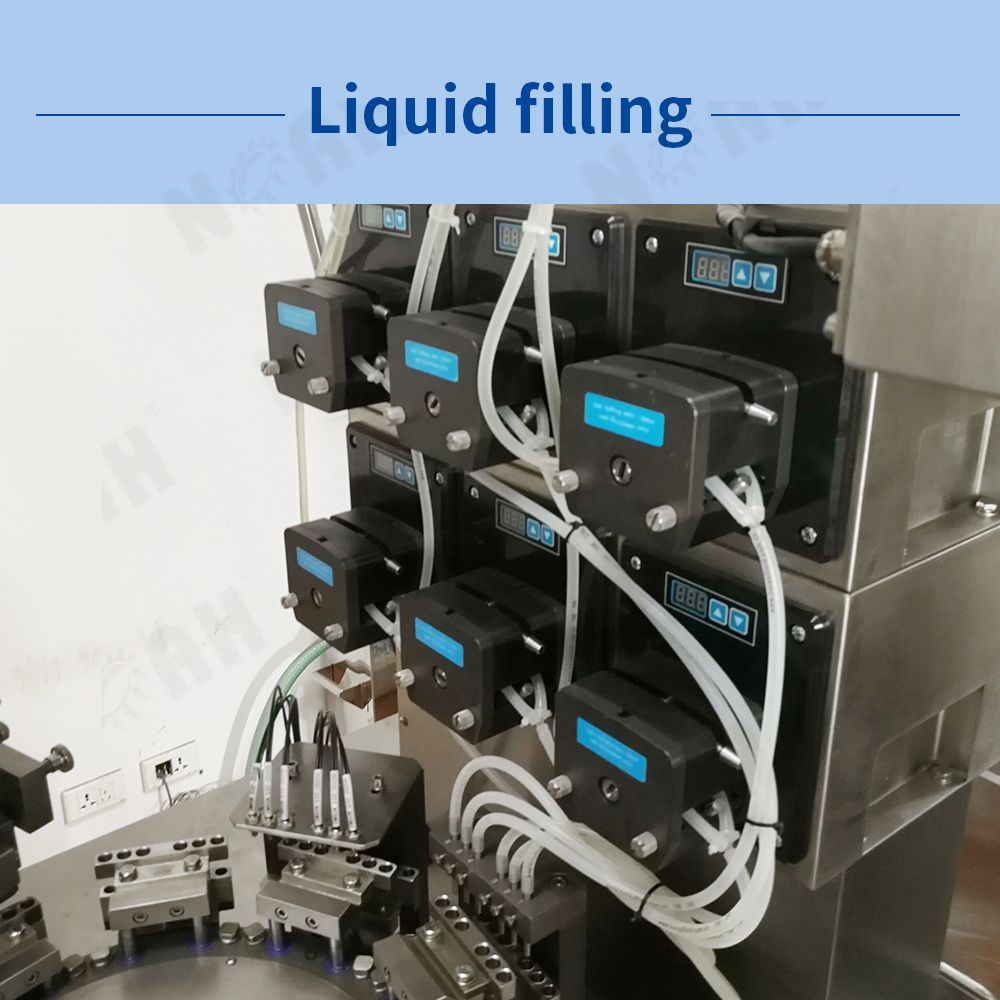

● Precise Filling: High-accuracy liquid filling system minimizes filling deviation, meeting NOAH’s strict quality control standards.

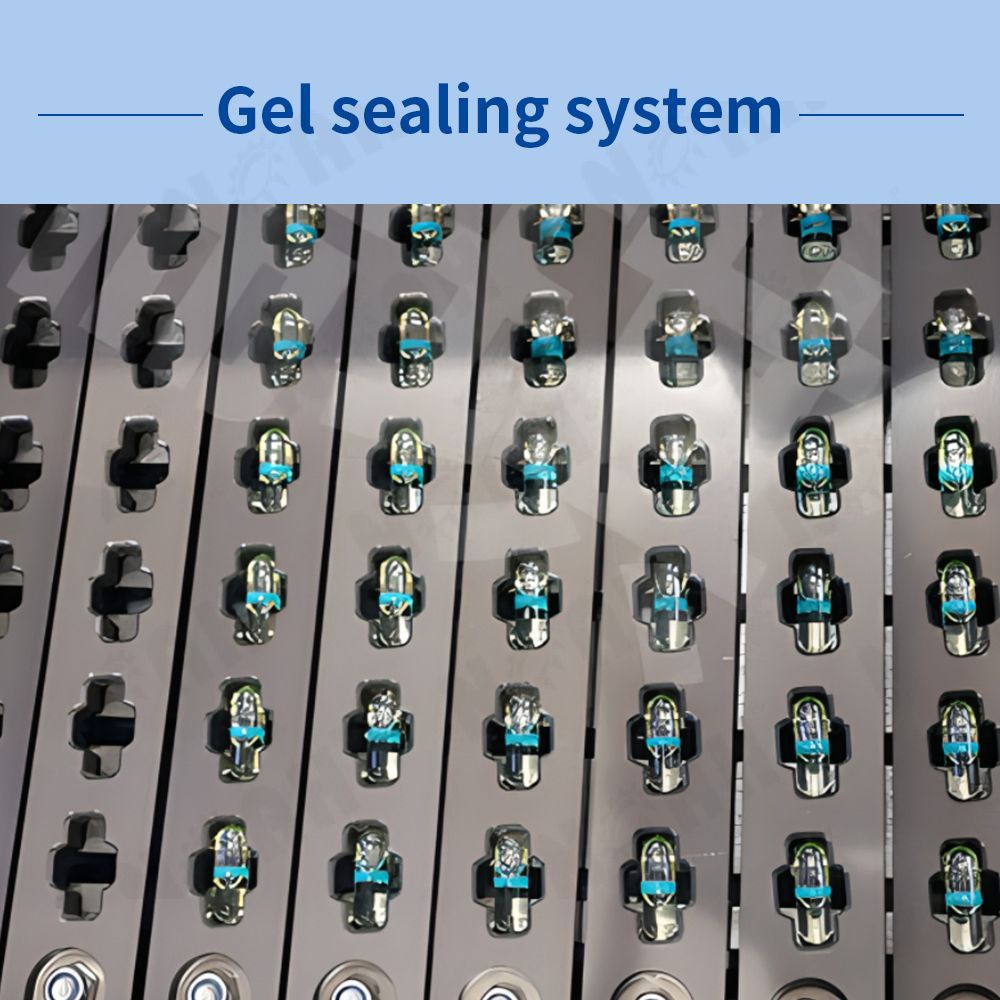

● GMP-Compliant Design: Optimized filling and sealing process for better process control and easy cleaning; strictly manufactured in line with GMP requirements—consistent with NOAH’s commitment to regulatory compliance.

● Intelligent Control: Equipped with Schneider PLC and touch screen, featuring an intuitive HMI for easy operation of all processes, designed for NOAH users’ operational convenience.

● Fault Alerts: Built-in alarm system for capsule shortage and liquid shortage, reducing downtime—part of NOAH’s efficiency-focused design.

● Versatile Sizing: The NJPF300 model (a key NOAH product) supports capsule sizes from #00 to #2, compatible with different filling volumes.

● Flexible Filling: Optional secondary filling station for multi-formulation applications (e.g., capsule-in-capsule, minitablets-in-capsule, pellets-in-capsule)—a flexible solution tailored by NOAH.

● Easy Maintenance: Modular design enables faster product changeover and cleaning, aligning with NOAH’s user-centric maintenance concept.

● Global Certification: CE-marked, meeting international quality and safety standards—NOAH’s guarantee for global market access.

Download

Download