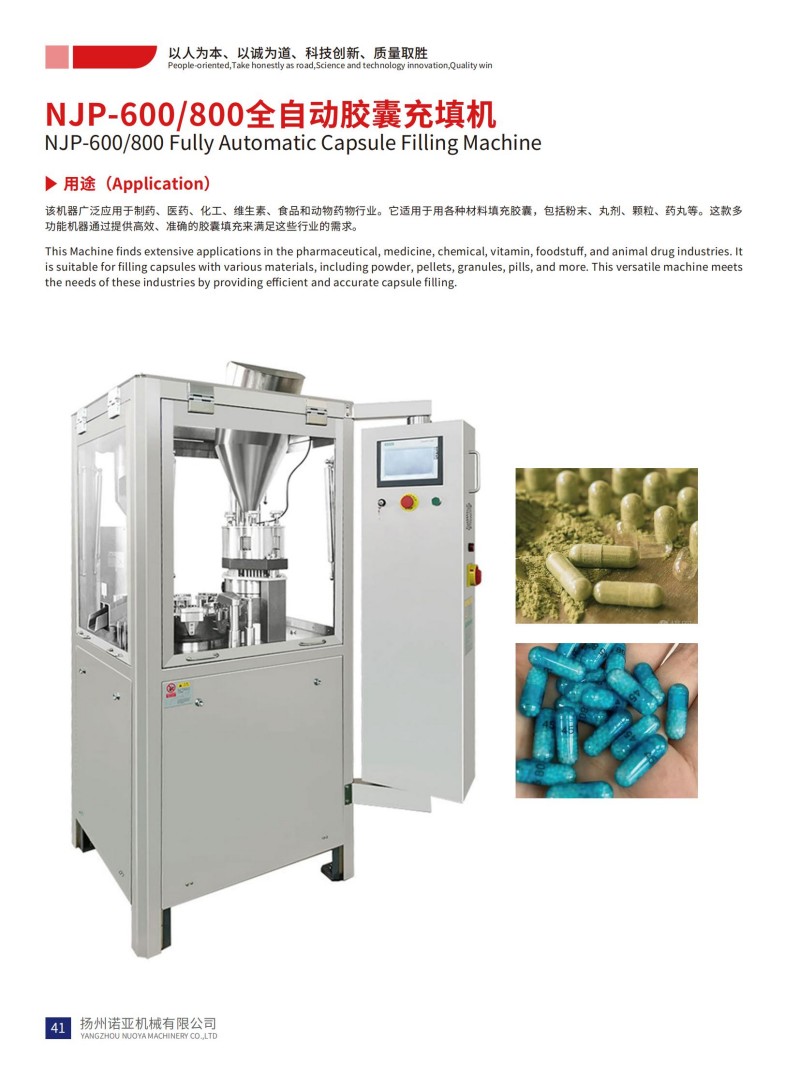

The NJP-600/800Fully Automatic Capsule Filling Machine finds extensive applications in the pharmaceutical, medicine, chemical, vitamin, foodstuff, and animal drug industries. It is suitable for filling capsules with various materials, including powder, pellets, granules, pills, and more. This versatile machine meets the needs of these industries by providing efficient and accurate capsule filling.

NJP-600/800 Fully Automatic Capsule Filling Machine

Discover the perfect solution for efficient and precise capsule filling with our top-of-the-line capsule-filling machine.

Download

Download