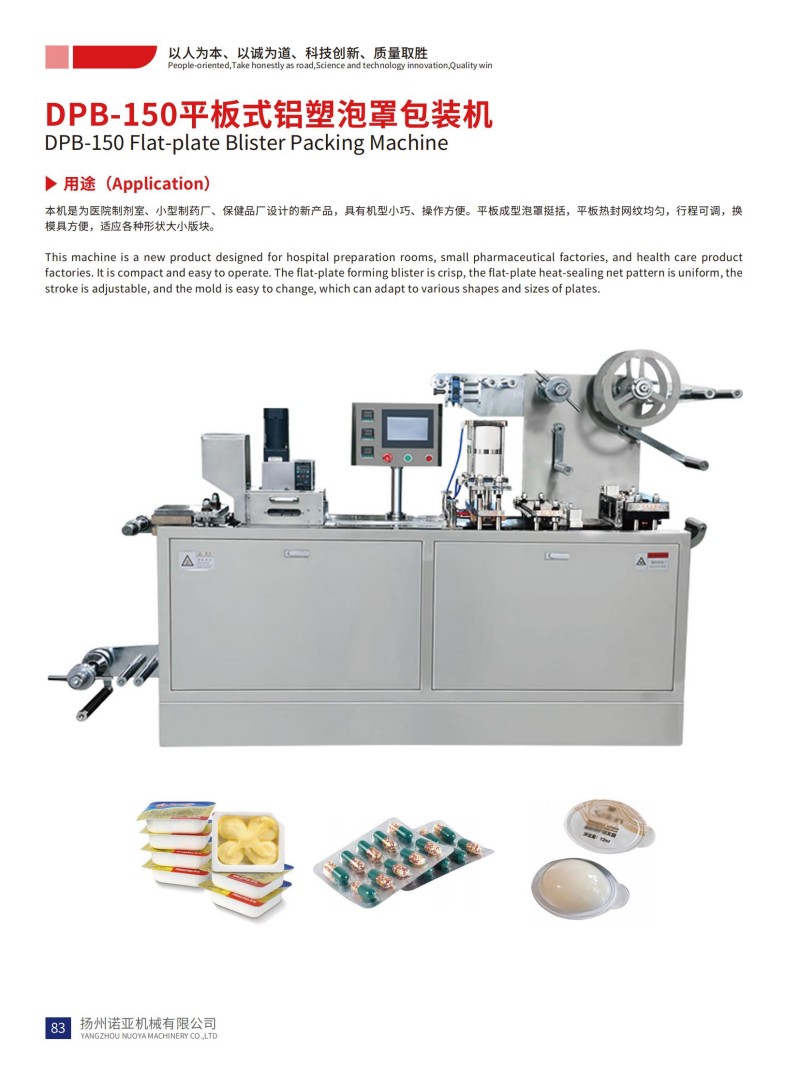

The DPB-150 Flat-plate Blister Packaging Machine is specifically designed for usage in various settings, including hospital dosage rooms, medium-sized and small-sized pharmaceutical plants, and health care product plants. Its compact size, ease of operation, and adjustable stroke make it ideal for these environments. It is used for packaging purposes in aluminum-plastic packaging, catering to the needs of the pharmaceutical, food, and electronics industries.

DPB-150 Flat-plate Blister Packing Machine

Experience seamless and efficient packaging with our high-performance blister packing machine, delivering secure and professional packaging solutions for a wide range of products.

Download

Download