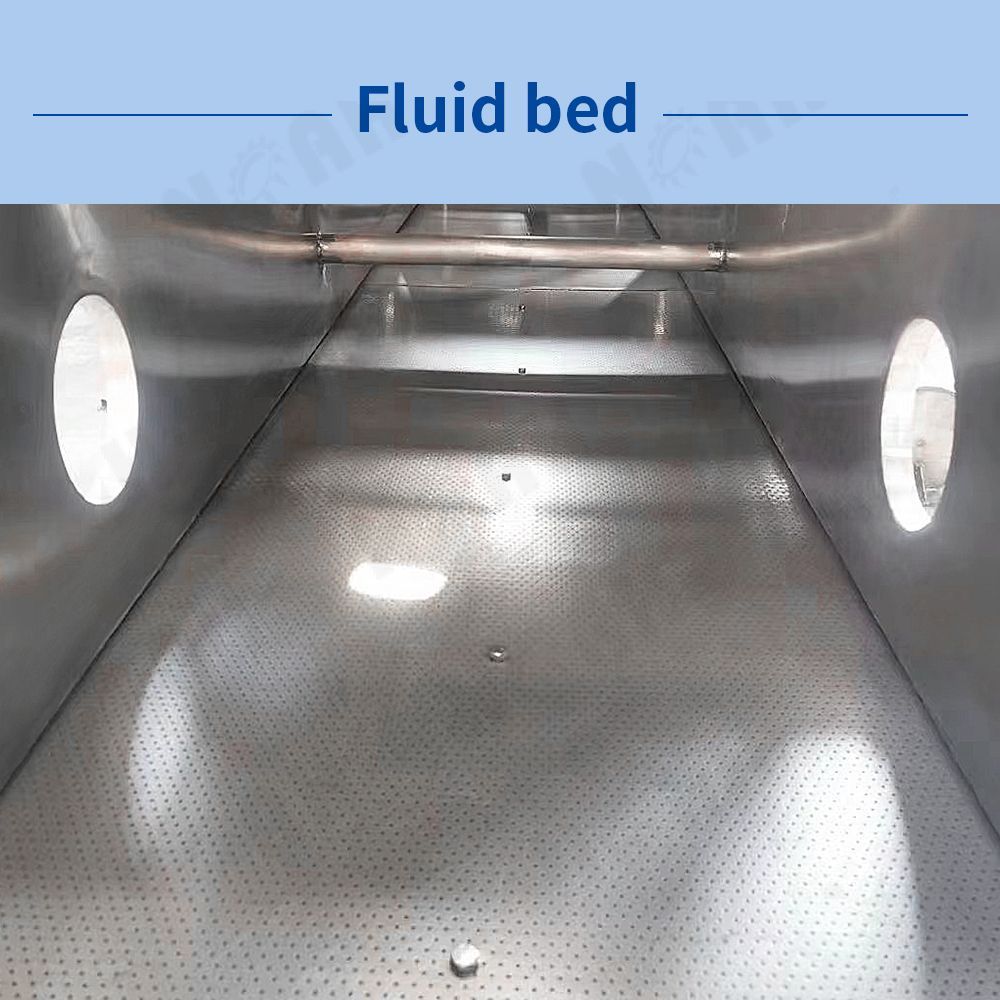

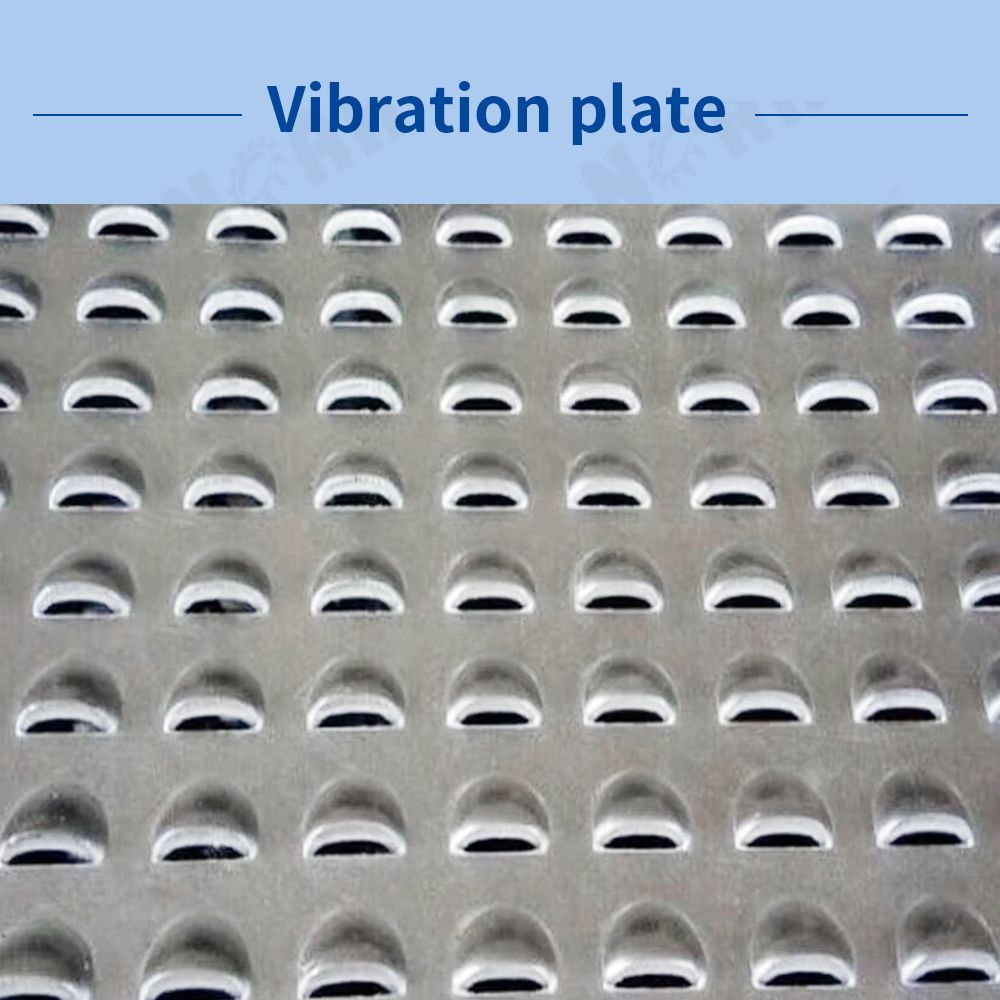

ZLG Series Vibrating Fluid Bed Drier is widely applied in various industries such as chemical, light, and pharmaceutical industries. It is also commonly used in the food processing, plastic, oil, salt, and sugar industries. This versatile drier provides efficient and reliable drying solutions for a wide range of materials in these industries, ensuring optimal quality and productivity.

ZLG Series Vibrating Fluid Bed Drier

Efficiently remove moisture and accelerate drying processes with our cutting-edge drying machine, ensuring optimal product quality and productivity.

Download

Download