HD series Multi-directional Movement Mixer is a novel material mixing machine widely applicable to industries such as pharmaceutical, chemical, foodstuff, and light industry as well as R&D. institutes. The machine can perform a very uniform mixing of power or granular materials with good mobility.

HD Type Three-dimensional Mixer

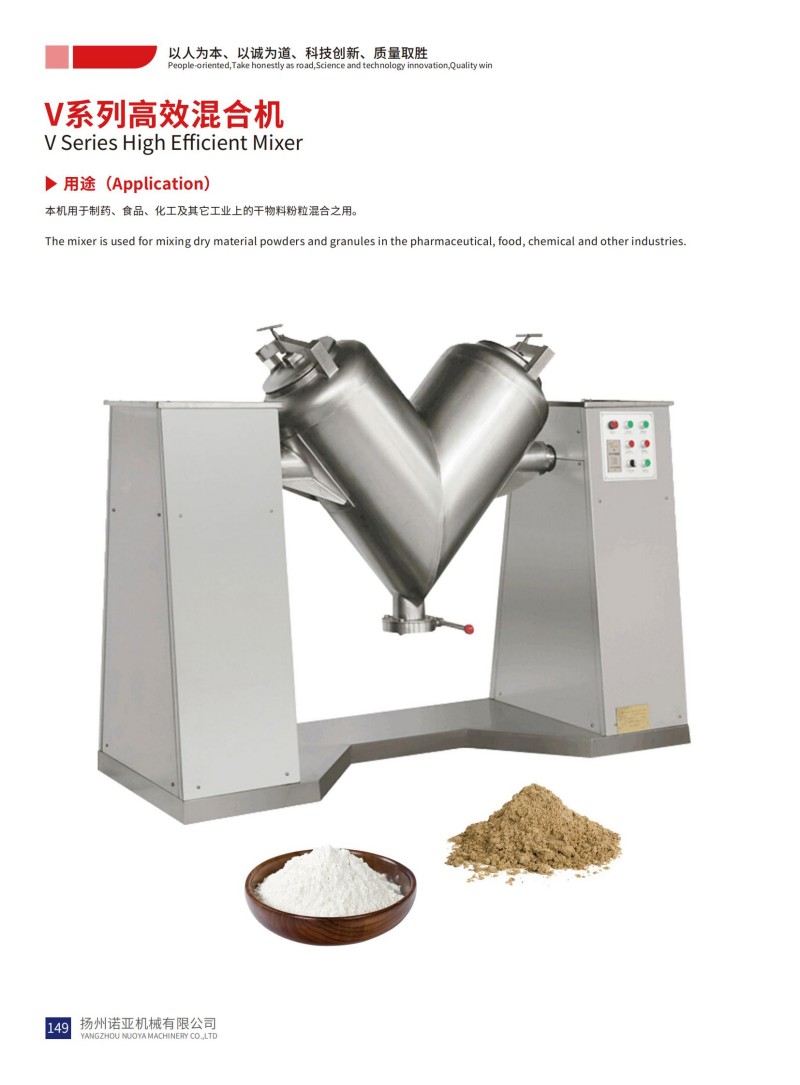

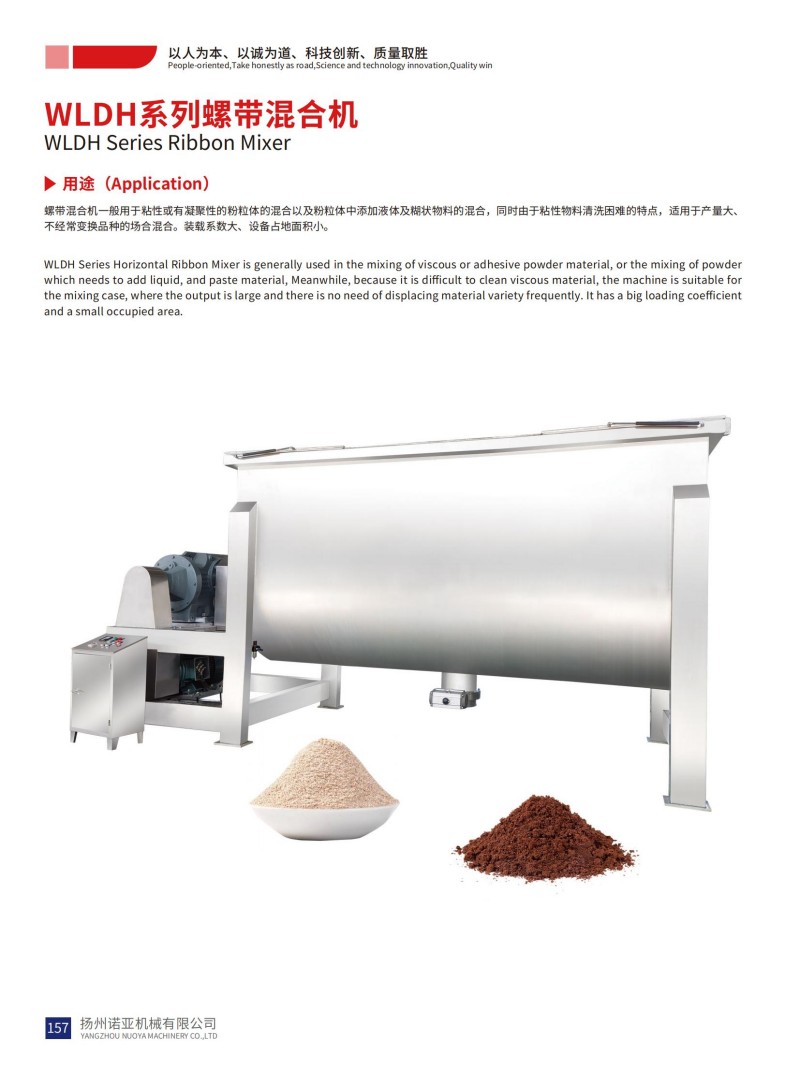

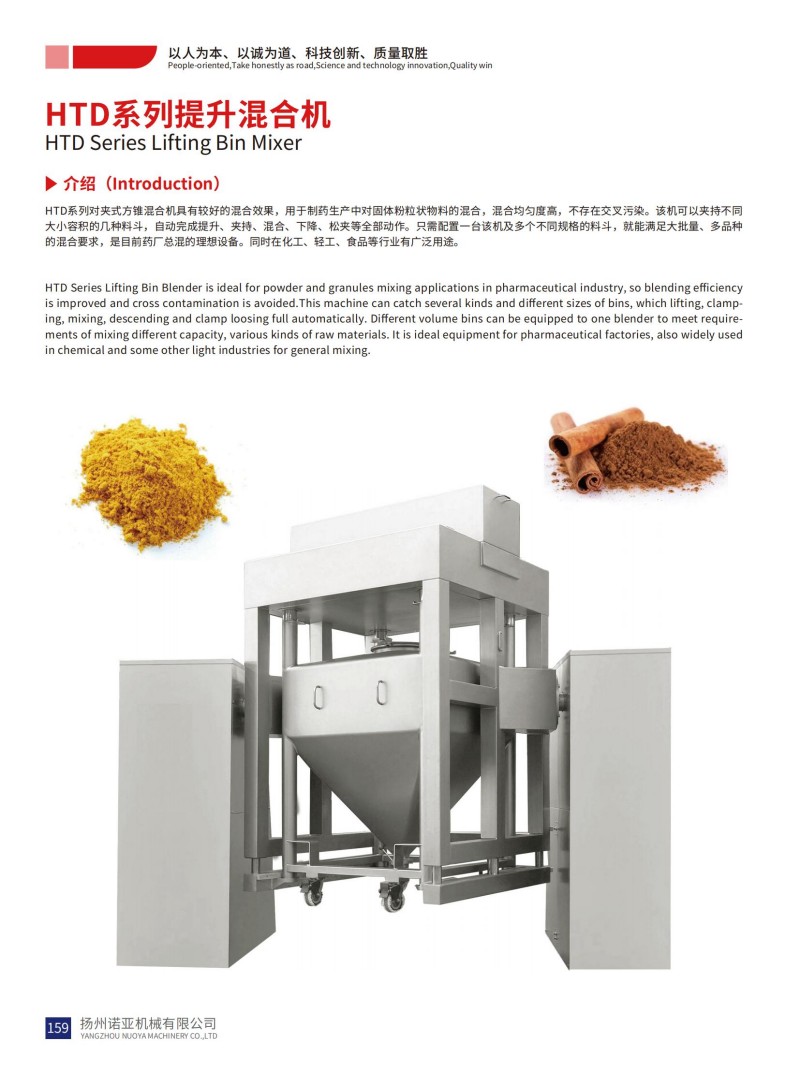

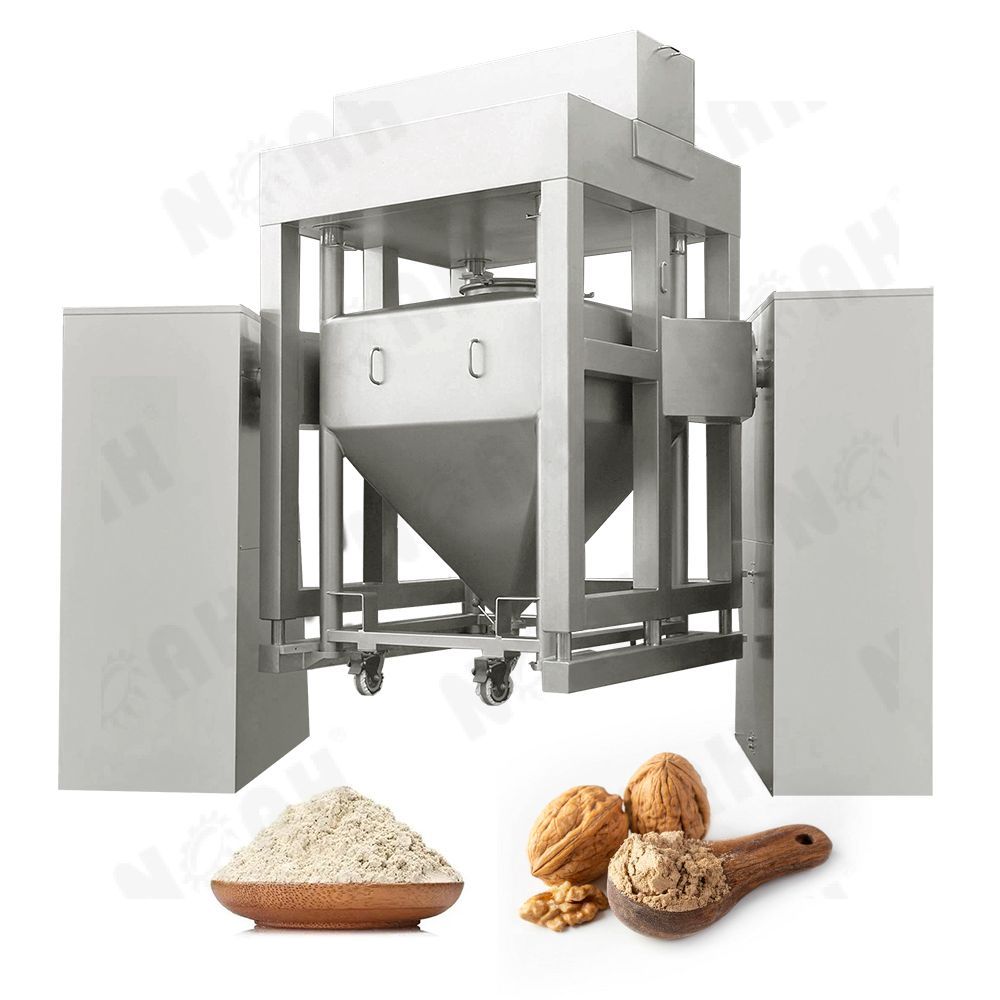

Discover the perfect blend of efficiency and versatility with our powder mixer, ensuring homogeneous mixing of powders for a wide range of industries and applications.

Download

Download