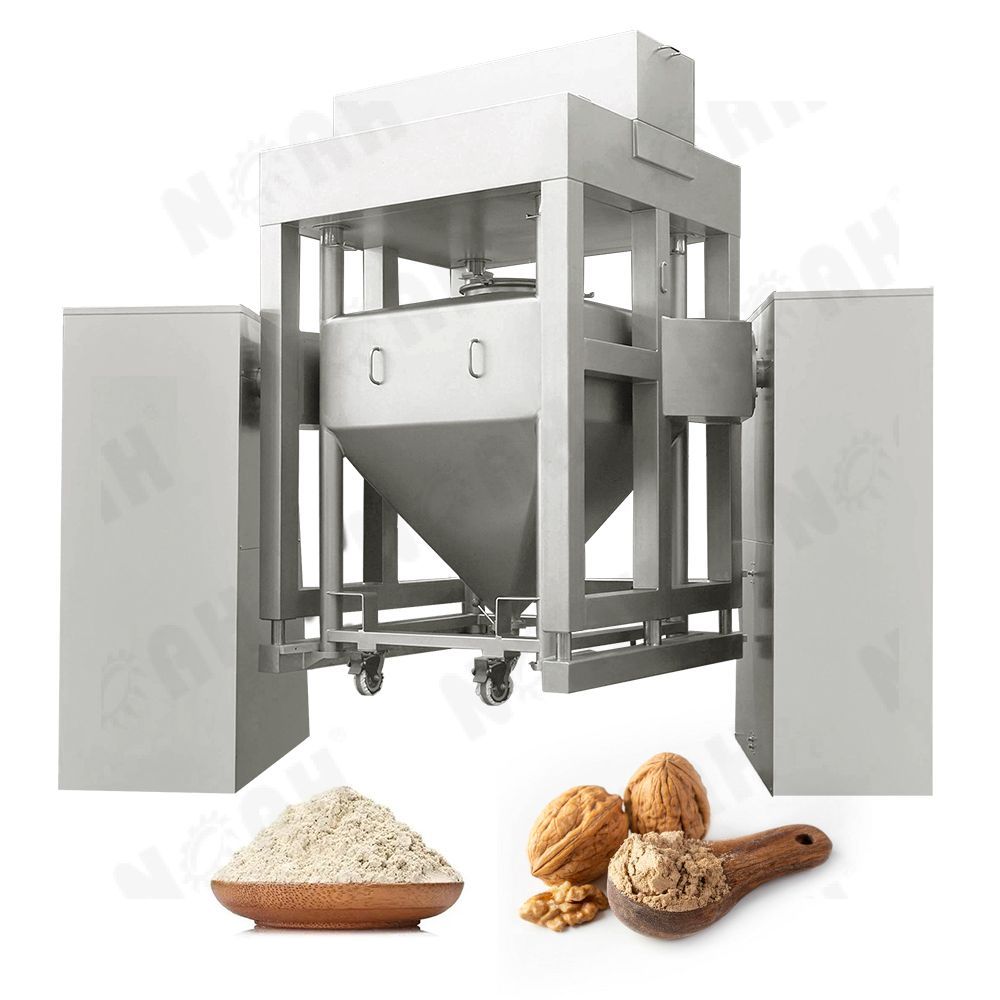

The CH Series Tank Type Mixer is widely used in pharmaceutical, chemical, and foodstuff industries. It is specifically designed for mixing powdery or paste materials, making it an essential machine for these industries.

CH Series Tank Type Mixer

Discover the perfect blend of efficiency and versatility with our powder mixer, ensuring homogeneous mixing of powders for a wide range of industries and applications.

Download

Download